Germany: Experts Analyse Solar Process Heat Market

August 31, 2013

Solar thermal systems are able to meet a significant portion of the heating requirements in many industrial and commercial settings. This is one of the results of an expert workshop entitled The Emerging Market for Solar Process Heat, which was organised by German research institute Fraunhofer ISE in Berlin in mid-June. One of the main topics of the workshop was the effect the improved conditions for solar process heat installations within the German Market Rebate Programme for Renewable Energies (MAP) had had on the market. Since August 2012 the MAP grants subsidies of up to 50 % of the net investment costs associated with the use of solar heat for thermal processes in industrial and commercial settings in Germany. The photo above shows the storage tanks of a solar thermal installation at a laundry. The tanks provide heat for the boiler feed water, the boiler make-up water and the washing machines.

The workshop took place at the invitation of the German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety, BMU, and the Fraunhofer Institute for Solar Energy Systems (ISE). Gerhard Schallenberg, responsible for renewable energies at the German Federal Office of Economics and Export Control, BAFA, elaborated on the terms of the programme in Berlin. Eligible for grants are solar thermal installations of up to 1,000 m². Plants above this limit can get partial support. Plants above 100 m² need to fulfil special requirements in terms of monitoring and error detection. The funding is also available for manufacturers of solar thermal installations which sell their own solar heat to customers (contracting).

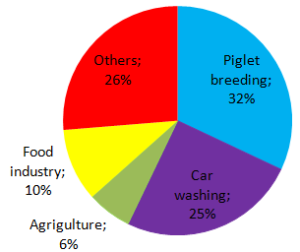

Subsequently, Schallenberg delivered some statistics about the first 50 approved installations in the 9 months since the start of the programme. Demand had increased significantly, as the BAFA registered only 59 solar process heat applications in the five years between 2008 and August 2012, and the quality of the submitted applications under the improved scheme was “generally good”, Schallenberg analysed in his presentation (attached document in German). According to updated information from BAFA, already 60 applications had been approved for support until the end of August 2013.

The most applications came from agricultural companies, followed by car washes and laundry businesses. Other projects came from the food and the animal feeding industry, as well as from fish farms. Three out of four installations have a collector area between 20 and 40 m², eight systems have a surface area between 40 and 60 m², three between 60 and 100 m² and only two are bigger than 100 m². One of the large systems is an air collector system and the other one is equipped with vacuum tube collectors.

According to Schallenberg’s presentation, only EUR 1.6 million were granted to process heat installations during the first nine months since the start of the approved scheme and 12 systems had been realised so far. He also listed some of the challenges faced by solar industrial applications:

- Extensive planning period, in average there were 9 months between approval of the rebate and installation of the system

- Low number of solar process heat engineers

- Little awareness among experts

- Technical concepts depend on industry sector

The workshop participants discussed the ways forward and the measures required to encourage more widespread use of solar process heat. The experts recognised family-owned businesses, which have no connection to the gas network and work closely with end customers, e.g., in the agricultural or service sector, as especially attractive markets for solar process heat. There would be an increasing need to develop standardised solutions for these target markets to reduce planning and installation costs. “There is still great potential in developing optimised system concepts and integrating solar process heat into complete industrial solutions,” says Dr Werner Platzer, Division Director Solar Thermal and Optics at Fraunhofer ISE. “Developing concepts which take industry-specific conditions into account and are also applicable to other industries is an important driving force in order to increase the use of solar process heat.”

The Fraunhofer ISE is currently working on a project to utilise solar process heat in laundries (SoProW), coordinating a consortium of organisations from the solar thermal, laundry, research and software development sectors. The aim of the research project, which is running until 2016, is to provide optimised and standardised solutions to generate solar process heat in laundries, and the range of tasks this work entails is diverse. In close collaboration with the Hohenstein Institut für Textilinnovation (translated as: Institute for Innovation in the Textile Industry), research will initially be conducted on the technical and commercial potential of using solar heat in the laundry industry.

The Fraunhofer ISE is also developing a scientific simulation environment, in order to assess different strategies for solar heat integration, and between three and five standard integration concepts are being incorporated into German simulation programme T*Sol created by Dr. Valentin Energiesoftware. Meanwhile, German Fresnel collector manufacturer Industrial Solar is looking for ways to modernise industrial heating networks by developing hybrid solar systems, in which Fresnel collectors work with various types of boilers in steam networks.

Together with solar companies Wagner & Co Solartechnik and s-power Entwicklungs- und Vertriebs GmbH, Industrial Solar is also carrying out the preliminary planning of three flagship projects to validate the developed design tools. Moreover, the project results will contribute to the IEA SHC Task 49 Solar Process Heat for Production and Advanced Applications.

More information:

http://www.bafa.de

http://www.ise.fraunhofer.de

http://task49.iea-shc.org

http://www.hohenstein.de

http://www.wagner-solar.com

http://www.s-power.de

http://www.industrial-solar.de

http://www.valentin.de