India: “The industry is one of the biggest energy consumers in the country”

December 20, 2012

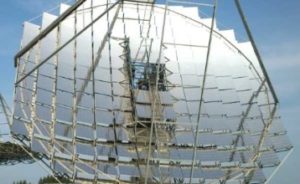

Indian company Clique Solar was among the award winners at this year’s Intersolar India in November 2012. For the first time, the international fair presented its Intersolar Award in the category of Solar Projects. The three awards went to outstanding projects in the categories of Industrial and Commercial Use, Off-Grid Solutions, and Utility Scale Projects. Clique Solar was founded in 1987 by a group of experienced engineers. The company is one of the very few in the region that has focused on expanding solar energy use in industrial process heat through R&D. One of the successful technologies developed by Clique Solar is the patented concentrating solar thermal system based on ARUN dishes. Solarthermalworld.org spoke with the two promoters of the company, Dr Shireesh B Kedare (left) and Ashok Paranjape, about their country, the new technology and their solar business.

Indian company Clique Solar was among the award winners at this year’s Intersolar India in November 2012. For the first time, the international fair presented its Intersolar Award in the category of Solar Projects. The three awards went to outstanding projects in the categories of Industrial and Commercial Use, Off-Grid Solutions, and Utility Scale Projects. Clique Solar was founded in 1987 by a group of experienced engineers. The company is one of the very few in the region that has focused on expanding solar energy use in industrial process heat through R&D. One of the successful technologies developed by Clique Solar is the patented concentrating solar thermal system based on ARUN dishes. Solarthermalworld.org spoke with the two promoters of the company, Dr Shireesh B Kedare (left) and Ashok Paranjape, about their country, the new technology and their solar business.

Photo: Clique Solar

Solarthermalworld: What is the benefit of developing Concentrating Solar Thermal (CST) technologies in India?

Paranjape: India’s high solar radiation on non-tracking horizontal surfaces for about 300 to 330 days a year – one of the highest in the world –is an ideal environment for using solar thermal. The industry is one of the biggest consumers of energy in our country. This means that the demand is already there and ready to be tapped – if the manufacturers of CST technology focus on making it a worthwhile effort.

The biggest and immediate application of CST heat is in steam generation below 250°C. This segment contributes to about 15 to 20% of India’s total consumption of oil (of which almost 80 to 90% is being imported). Cooling and air conditioning are other energy-intensive applications.

Solarthermalworld: What prompted Clique Solar to venture into CST?

Kedare: We started using concentrating solar thermal power in the late 1990s simply because we had the expertise and the dedication to do it. We wanted this technology to develop into a viable option for various industries. It makes us happy that we have been able to develop our ARUN solution – which is not only a unique technology, but also a technology relevant to our consumers.

Industrial products, such as processed food (dairy, seafood and sugar), textiles, pharmaceuticals, pulp & paper, chemicals, automotive components, etc require a huge amount of thermal energy during their manufacturing process and their industries will chiefly benefit from using CST technology. This meant that our aim had already been established.

Solarthermalworld: What are the particular characteristics of an ARUN dish?

Kedare: ARUN uses a two-dimensional, Fresnel-type mirror arrangement to concentrate energy in one point. It automatically tracks the sun from sunrise to sunset on both the east-west and north-south axes in order to absorb the most sunlight. The special dish design achieves the highest thermal energy output per m2 of collector area of any solar concentrator in India. The small footprint area of an ARUN dish (3m x 3m per dish) means it can be mounted at locations with limited space. The dish can operate up to 4,000°C (oil) and 25 bar (steam). It can also be augmented with a heat energy storage facility to operate during hours without sunshine.

Solarthermalworld: Can you tell us more about the project which qualified you for the Intersolar 2012 award?

Paranjape: The solar cooling system installed in the city of Greater Noida, Northern India, operated by the National Power Company (NTPC) and consists of two ARUN 160 dishes with a reflector area of 169 m2. The dishes provide saturated steam at 8 bar to a vapour absorption machine with 50 Tons of Refrigeration (TR). The process starts by letting treated water circulate at ambient conditions inside the receiver coils of the ARUN dishes until the desired fraction of steam has been generated. The steam will then be split up in the moisture separator on the outside of the dish. To supply chilled water (7 °C) to the rooms, the vapour absorption machine is using fan coil units. A certain amount of cold water is also stored inside the chilled water tank (550 m3). The storage facilities represent a unique part of the project.

Solarthermalworld: What are the results of the NTPC project so far?

Paranjape: We have just commissioned the dish, so we are still monitoring performance and stability. We should be able to share the respective figures in a few months.

Solarthermalworld: What are the challenges that need to be overcome in order to achieve commercial viability?

Kedare: The biggest challenge is making people aware of the benefits which CST has to offer. Talking about industrial consumers who require steam/heat energy, the challenges can be categorised as follows:

- Application – Heat requirements range from 50°C to 400°C. Technologies which cannot deliver the right temperature level will not find acceptance among clients. Hence, the crucial point is to provide stable and accurate temperatures.

- System Economics – The key issue here is a fast return-on-investment through large savings in fossil fuels and an easy maintenance.

- Space – If the system is economically feasible, but there is no ground space available, the client will not invest. Also, it is essential that any CST technology can be integrated into an existing system.

Solarthermalworld: What are the niche areas in which CST could prove viable and shows promise?

Paranjape: Ideally, any process which requires steam shows immense potential for CST use. The important part is to develop the relevant technologies. We have already listed the industrial sector at the beginning of our interview. Tremendous interest in the technology has also come from the area of mass cooking with solar-run and steam-based jacketed vessels, especially at the community level, such as in temples or hotels. Hybrid solutions for solar cooling which are coupled with sea water desalination may also have a bright future ahead.

More information:

http://www.cliquesolar.com

http://www.ntpc.co.in