SHIP feasibility assessment within a few hours

July 4, 2019After four years of intensive scientific-technical work, the Association of German Engineers, also known as VDI, will soon publish VDI 3988, a guidance document intended to support the preliminary design of systems that supply solar heat for industrial processes (SHIP). The document will be released in a bilingual German and English version and include a methodology for estimating heat production costs. It is planned to be published in August and can then be ordered online. The photo, taken in Greece, shows a SHIP system consisting of covered parabolic trough collectors manufactured by a Swedish-based supplier.

Photo: Absolicon Solar Collector AB

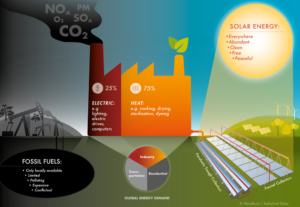

“Despite great potential and incentives that have covered up to 50 % of the costs since August 2012, Germany has yet to see notable growth in the solar process heat market,” said Thomas Schabbach, a researcher and lecturer at the Nordhausen University of Applied Sciences. Because of this, the solar industry launched an eight-person committee made up of researchers and industry professionals to draw up new guidelines on designing solar process heat systems. The aim of the document is to help consultants and planners complete the preliminary design phase with greater ease and decrease the relatively high cost of feasibility studies, for which money is usually scarce.

In May, Schabbach and Dominik Ritter, who works at the University of Kassel, presented VDI 3988 at the Solar Thermal Energy Symposium, the science and technology meeting of the German-speaking industry, in Bad Staffelstein. Schabbach said the guidelines were essentially based on a booklet, titled Guidance on Pre-planning Solar Process Heat Installations, which had been created by the University of Kassel and discusses the preliminary planning phase of solar process heat installations.

The new document will reflect current developments and technological advances in the industry and set uniform standards to prevent typical planning and installation errors. It will help with all relevant stages of designing and putting up SHIP systems. “The guidelines are aimed not only at planners and developers but also contractors,” said Schabbach, so as to give stakeholders greater planning certainty. The authors of the document have focused on identifying basic requirements for speeding up preliminary planning and on providing reliability throughout the process.

Eight German experts have been involved in drafting VDI 3988. They are:

• Alexander Neupert, Bosch Solarthermie

• Bastian Schmitt, University of Kassel

• Dominik Ritter, University of Kassel

• Frank Kohnen, expert in building services

• Lars Staudacher, ZAE – Bavarian Centre for Applied Energy Research

• Thomas Fackiner, Viessmann Germany

• Thomas Schabbach, Nordhausen University of Applied Sciences

• Werner Platzer, Fraunhofer Institute for Solar Energy Systems ISE

Feasibility studies take few hours

The above means that to create the preliminary design of a collector surface, suppliers will need only a small amount of data from industrial customers. “Under ideal circumstances, VDI 3988 will make it possible to prepare feasibility studies in a few hours. They can then be used for decision-making and, if needed, to start detailed planning,” said Schabbach.

The guidelines will also provide help with selecting the most suitable hydraulic design, as well as with choosing the most appropriate design graphs, which have been created from detailed simulations for a variety of locations and collector types. In addition, these graphs will show possible orientations for storage tanks based on load profiles, heat sinks and flow and return temperatures. Likewise, they can be used to estimate the cost of producing solar heat based on a specific preliminary design and pick a calculation method for conventional heat production to determine the economic viability of new ideas.

Organisations mentioned in this article: