“PVT heat pump systems will become standard in the Netherlands”

March 1, 2024

After France, the Netherlands has the largest specific PVT area installed per 1,000 inhabitants in Europe. At the end of 2022, a total of 111,342 m2 of PVT collectors were in operation. Between 30,000 and 40,000 m2 are added every year. A well-established Dutch industry offers PVT elements. We spoke to two PVT manufacturers about the reasons for the widespread use of PVT. The photo shows a new development area in Utrecht with a typical PVT heating solution. Each of the 100 to 120 m2 apartments has a 3 to 4 kW heat pump connected to an individual PVT field on the roof. Not a single outside fan unit for an air-source heat pump is installed in this compact development.

Photo: Triple Solar

“In the typical terraced houses in the Netherlands, house owners are concerned about the relationship with their neighbours if there is noise pollution from air-source heat pumps”, explained Cees Mager, founder and Managing Director of Triple Solar, a manufacturer of PVT elements and heat pumps.

Mager founded the company in 2009 with the aim of developing a thermal panel as an energy source for heat pumps. In 2016 Triple Solar joined forces with Consolar in Germany and they developed the current generation of PVT heat pump panels. They have a large metal fin-tube heat exchanger that is fixed behind the PV module. This PVT panel became the sole source of heat for brine heat pumps. In the last decade, Triple Solar reports it has equipped more than 6,000 apartments and buildings in the Netherlands with PVT solutions.

Newly built heating systems have to be all-electric

“All-electric has been the rule for new buildings in the Netherlands for several years now, so heat pumps are standard in this segment”, said Bart Gehoel, giving another argument for the growing demand for PVT solutions. He is Sales Engineer Heating Solutions at the Dutch company Alius, which has been offering PVT solutions for seven years. Alius started in cooperation with R & R Systems, another established Dutch supplier of PVT solutions. But in 2022 Gehoel and his team launched their in-house developed Volthera PVT element. It consists of a ribbed aluminium absorber with copper pipes (see photo below). “The big advantage of this element is the high heat exchanger surface, so that fewer PVT elements are needed per housing unit”, explained Gehoel. Alius is cooperating with the German heat pump manufacturer Vaillant and together they have optimized the brine heat pump from 3 to 15 kW so that it can now use brine from the roof down to -10 °C as a heat source.

Volthera PVT collector in operation (left) and from the back (right): The ribbed absorber is not connected to the PV module but both elements are placed on the mounting system and are fixed there. Photos: Alius

Hybrid solutions with heat pump and gas boiler are popular

When renovating buildings, heat pumps are often used as a supplement to the existing gas boiler. In this case, the gas boiler can take over the heating on cold winter nights with temperatures below zero, when the heat pump would run inefficiently. “The PVT heat pump systems become significantly more expensive if they also have to cover the last 20 % of the heating requirement in winter”, explained Gehoel, indicating the pragmatic approach.

“A well-designed PVT heat pump heating system can save 80 % of the gas over the year, even in old buildings, which is why hybrid solutions with gas boilers are very popular in Holland”, confirmed Mager. Triple Solar reacted to the demand for small heat pumps for hybrid installations by launching an in-house developed 3.5 kW PVT heat pump in 2023.

With this product, Triple Solar mainly wants to address the segment of retrofitting buildings of housing cooperatives. Mager quantified this market segment as having four million units across the Netherlands owned by cooperatives and professional rental companies. “The government puts high attention and high subsidies into retrofitting this building segment, where heat pumps as hybrid solutions are very common”, said Mager.

Renovated terraced houses belonging to the De Woonschakel housing cooperative in the Netherlands are completely heated with PVT collectors and heat pumps. Photos: Triple Solar

Far-reaching restrictions for borehole drilling

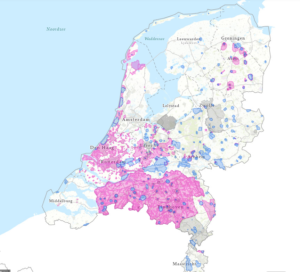

Previously, geothermal heat pumps with boreholes were frequently used for new buildings. Drilling of boreholes is now severely restricted in many regions of the Netherlands. Mager refers to the map of WKO-Bodemenergietool – literally translated as Ground Energy Tool (see graphic below). Drilling is restricted in all areas coloured blue, pink and grey on the map. The reasons for limiting the drilling depth include the fact that in many areas of the Netherlands beverages are produced that require pure water from the aquifers.

In Mager’s opinion, PVT heat pump systems will become standard in these areas, as it is too expensive to drill a large number of short boreholes. In other areas such as Delft it is forbidden to use air heat pumps in new buildings because of the noise pollution.

In the areas marked in pink drilling is restricted because of provincial policies. In the grey areas the depth is restricted to around 20 to 30 metres and the blue areas are protected areas for drinking water. Source: https://wkotool.nl/

Websites of organizations mentioned in this news article:

Triple Solar: http://www.triplesolar.eu

Alius: https://alius.nl/

R & R Systems: https://www.energieverdieners.nl/

Consolar Solare Energiesysteme: https://www.consolar.de/en/home_en/