Norway: 15 Years of Research on Polymer Materials for Collectors

May 26, 2010

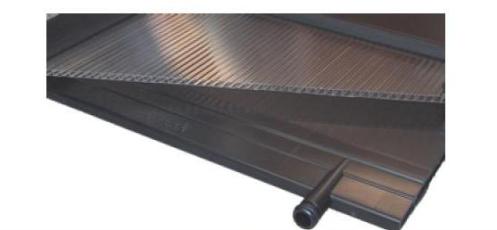

This prototype of a plastic absorber by Norwegian company Solarnor was never produced in series. The company filed for bankruptcy at the beginning of the year.

This prototype of a plastic absorber by Norwegian company Solarnor was never produced in series. The company filed for bankruptcy at the beginning of the year.

Photo: Solarnor

The end of 2009 also marked the end of Solarnor, a Norwegian company, which was renowned for using polymer materials in solar thermal absorbers over the last 15 years. As shareholders stopped their investments, the company went bankrupt. Former CEO Hans-Christian Francke then bought up the company’s assets, such as its intellectual property, patents and tools and founded a new company called Catch Solar Energy AS on 1 February 2010.

“We are about to patent a completely new technology, which will be introduced in September this year,” Francke announced. It will have nothing to do with polymers, because Francke is convinced that the experience with Solarnor showed how “plastic is not going to work in solar thermal collectors even with the extensive help of the world’s largest expert, SABIC Innovative Plastics”. “The heat conductivity in plastic is small; you have to decrease the thickness of the absorber to have a fair heat exchange, which will make the material very prone to ageing,” Francke names one of the difficulties with it. “Increasing the thickness would increase both the costs in a substantial manner and decrease its efficiency”. According to Francke, one must also consider that plastics usually expand greatly in size because of their thermal characteristics, which means the material will bend during high-temperature operations. The material’s third disadvantage is its lack of durability at those same high temperatures (170°C and more are common during absorber production) and a lack of UV-resistance.

John Rekstad, on the other hand, seems more optimistic about the future use of polymer materials in solar thermal systems: “There is no doubt that, in the future, polymer materials will play a significant role in the solar thermal industry.” The researcher from the University of Oslo and founder of Solarnor sees two possibilities for creating a long-lasting collector with a polymer absorber: The first is to use high-quality polymer materials, which can withstand common absorber temperatures of far above 150°C in the long run. Their disadvantage: They are expensive and demanding during further processing steps.

According to Rekstad, the second possibility is to use medium quality polymers, which are more cost-effective but need to be shielded against too much heat. Finding a solution to that dilemma was one of Solarnor’s research projects over the years. “We introduced an overheat protection, which was based on a ventilation device controlled by the thermal expansion of the absorber. It reduced the stagnation temperature by between 20 K and 30 K. This gave sufficient protection in climates where the maximum summer temperature seldom exceeded 30°C,” Rekstad explains. The polymers provided by cooperation partner GE Plastics, the plastics division of General Electric (now SABIC Innovative Plastics), were the best materials around ten years ago, but they were only able to withstand temperatures of more than 120°C for a couple of hours.

More information:

Catch Solar Energy AS: http://www.solarnor.no

University of Oslo: http://www.uio.no/english