“Made in Taiwan is a brand name which still sells”

March 17, 2011

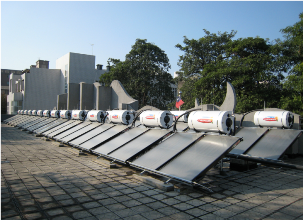

Taiwan remains a country strongly dominated by flat plate collectors. Solarthermalworld.org spoke with local solar thermal manufacturers and planners about the advantages of the technology in comparison to vacuum tubes. The photo shows an installation at the elementary school in the municipality of Jin-Yue – planned and installed by Taiwanese company Wang Aun.

Taiwan remains a country strongly dominated by flat plate collectors. Solarthermalworld.org spoke with local solar thermal manufacturers and planners about the advantages of the technology in comparison to vacuum tubes. The photo shows an installation at the elementary school in the municipality of Jin-Yue – planned and installed by Taiwanese company Wang Aun.

Photo: Wang Aun

Taiwanese solar thermal water heating system manufacturers confirm that flat plate collectors are still used in 90% of all installations. With an estimated 12,000 m2 of national monthly production capacity, the solar water heating industry is dominated by flat plate collector manufacturers. Although mainland Chinese manufacturers try to import cheaper vacuum tube collectors, Taiwanese prefer flat plate technology in industrial and private installations.

One reason for this predilection is the focus of Taiwanese customers and project developers on Taiwan’s own manufactured products, which are publicly promoted due to the island’s political situation with its big neighbour. “Although we export to the Pacific region, including New Zealand and Australia, 90% of our market volume remains in Taiwan,” John Lin, Managing Director of Sansung, a major manufacturer of flat plate collectors, says. “’Made in Taiwan’ is a brand name which still sells – we are proud of our products.” Peggy Kuo, Director International Operations at Suncue in Taichung confirms that although there are thoughts about diversifying from a strong home market, which counts for 80% of production output, Taiwan will remain a stronghold and the main focus.

Secondly, quality is still a vital factor in the decision to use flat plate collectors. The technology is more suitable for the island’s high frequency of typhoons and regular earthquakes. The importer and project developer Wan Aun’s General Director Peter Tsai explains that his company has been installing flat plate collectors for over 30 years. “Although we only import thermosiphon systems – mostly direct systems – we can guarantee the highest quality for bigger dormitory and university projects. Vacuum tubes from China are not an option for a developer with sustainability in mind, rather than just making a short-term profit.”

“Vacuum tubes do not withstand the pressure requirements with over 8 bar that most users have. After 3 years, even pressurised vacuum tubes start leaking and need to be replaced,” is the explanation from Homemark’s Allen Chen. Homemark, a holder of several patents for water storage and water heating systems and the biggest stainless-steel tank manufacturer in Taiwan, states that pressurised storage systems are commonly used throughout the country’s high density of households.

Yi Wei Hsu, General Manager of Sunpool, a leader in providing heating systems for swimming pools and assembler of stainless-steel flat plate panels from Taichung, also confirms that pressure is a critical argument against vacuum tube panels. That is why Sunpool uses EPDM pipes and stainless-steel flat plate collectors for its projects, of which 12,600 m2 have already been installed. Additionally, Taiwan’s “heavy mineralised water” (source: MOEA, Water Resources Agency) destroys vacuum tubes faster than stainless-steel flat plate collectors. Taichung’s Sunpool uses SUS304 stainless steel and sees problems due to mineralised water in all parts of the water heating process – especially in the absorbers.

“To make things simple,” Allen Chen summarises the mood of the solar thermal industry in Taiwan: “Price is not the only reason why investments are made in Taiwan – quality, especially when “Made in Taiwan”, is still important in decision-making.”

More information:

http://www.homemark.com.tw

http://www.suncue.com

http://www.sunwepool.com

http://wangaun.com

http://www.sansung.com.tw

http://www.moea.gov.tw

This article was written by Johann Pacher, Managing Director of Faros Consulting Pte Ltd, a company specialised in renewable energies and based in Singapore http://www.farosconsulting.com.