Australia: Country to Publish First Solar Air Conditioning Standard

In April, two workshops for solar cooling took place in Asia. At the beginning of the month, a workshop in Singapore focused on the use of solar cooling in tropical regions and gathered around 70 participants from research and industry (see photo). The workshop took place at Cleantech One, which is part of Singapore’s clean technology centre. Cleantech One also hosts the Asia office of Austrian turnkey system provider S.O.L.I.D. and the energy research institute ERI@N of the Nanyang Technological University (NTU). They both organised the workshop together with the International Energy Agency (IEA). A week later, almost 80 solar cooling specialists participated in the Australian Solar Cooling 2013 Conference in Sydney, an event by the Australian Solar Cooling Interest Group (ausSCIG). Solarthermalworld.org has picked out the highlights from the presentations held at the two workshops.

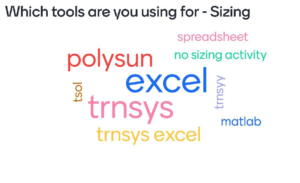

In Sydney, Jeremy Osborne from Solem Consulting, Australia, presented a new standard to calculate the energy savings from packaged solar cooling and heating systems (see the attached paper). The new standard is currently called DR AS 5389: “Solar cooling and heating systems –Calculation of energy consumption”. Until now, the scope of the standard has been limited to DEC systems with desiccant wheel technology (a dehumidification technology frequently used in air conditioning systems).

Osborne explains the relation to solar thermal as follows: “Desiccants can be reused over and over again, but need to be recharged through heat, e.g., boil off the water that has been captured within the desiccant material. This can be done using any heat source, such as solar thermal collectors, gas or both.” A solar storage tank can be incorporated into the desiccant system to supply the hot water to the desiccant in summer, to a heating system in winter and also through both to a domestic hot water system.

The standards committee worked with CSIRO, Australia’s national science agency, whose commercialised desiccant wheel technology provided the technical data relevant to the development of the standard. “We started with one technology because we did not want to overcomplicate the process,” Osborne says. Additional technologies, such as absorption and adsorption chillers, could be added at a future time.

The standard enables the calculation and comparison of the energy consumption of a solar-driven desiccant system and it can also help estimate the heating and hot water generation potential.

The performance calculation approach is based on Component Testing – System Simulation (CTSS), which means that the major components of a complete system are performance-tested one by one, under pre-specified conditions. A rating for a complete system can then be calculated by simulating the interaction between the individual components, using the methods outlined in the standard. The draft standard includes a document explaining the simulation method and a sample TRNSYS simulation studio file.

The standard has been under development by the Australian Standards committee CS-28 since June 2011. An interim version is expected to be released and available for purchase in July 2013. As it is an interim version, it will have an extended two-year public comment period. Over this period, the standard will be revised according to international developments and the feedback from the local industry.

Dr Uli Jakob from European industry association Green Chiller and from Solem Consulting in Europe gave an update on solar cooling technology and market development in Sydney (see attached presentation). The variety of thermal chillers keeps increasing. There are new chillers for very small systems down to 5 kW, for example, by Makatec (Germany) and Solabcool (Netherlands). There are also new cooling kits including integrated heat rejection by Solabcool, Mitsubishi Plastics (Japan) and Jiangsu Huineng (China). The solar cooling market had grown about 30% each year over the past 8 years. In 2012, about one thousand solar cooling systems were installed worldwide.

Just shortly before the conference in Australia and 4th IEA-SHC Task 48 Experts Meeting, the Asian subsidiary of Austrian company S.O.L.I.D., the international Energy Agency IEA, the Nanyang Technological University (NTU) and the Austrian embassy in Singapore organised a workshop on solar cooling in Singapore (see photo above). Most of the 70 participants came from Asia. The workshop took place at Cleantech One, which is part of Singapore’s clean technology centre and also hosts the Asia office of S.O.L.I.D. and the energy research institute ERI@N. The list of participants shows how solar cooling has evolved: Besides scientists, the participants were companies interested in the installation of solar cooling systems, as well as bankers and other investors. A visit to the solar cooling plant at the United World College was an integral part of the workshop. Because it is an ESCO project, the investors showed great interest in the project.

The COP measurements at the plant were between 6 and 14. “This is extremely high. The COP of most existing plants stays below 10,” said Jakob. Project developer Moritz Schubert from S.O.L.I.D. presented the plant’s operational data and how operation had been optimised.

For example, high heat losses in the pipes of the solar circuit were a problem during the first months the plant was running. In the morning, it took long to heat up the pipes to the required temperature of 90 °C for the absorption chiller. This temperature has been reduced in the meantime: Now, operation starts in the morning when 75 °C is reached in the absorption chiller. “It turned out that the chiller can work at 60 °C. But, of course, we try to achieve higher temperatures. During the course of the day, we usually achieve more than 80 °C and this with a high efficiency,” says Schubert. But although a high efficiency is a plus, his priority is rather a high cooling. Whenever the high temperatures are not available, the absorption chiller has to deal with lower temperatures. At the end of the day, all the heat which is not produced by the absorption chiller will have to be provided by an all-electric back-up chilling system. This means that with regard to complete systems, maximising the solar cold is also the most efficient operation mode. S.O.L.I.D. sees potential in further increasing the efficiency through optimising the pumps of the heat rejection.

More information:

http://task48.iea-shc.org/workshop01

http://www.ausscig.org/conference.html

http://www.solid.at/index.php?option=com_content&task=view&id=262&Itemid=1

http://www.solem-consulting.com

http://www.csiro.au

http://www.solid.at

http://www.csiro.au/Outcomes/Energy/Renewables-and-Smart-Systems/solar-power.aspx