Fine-tuning phase change materials

May 24, 2024

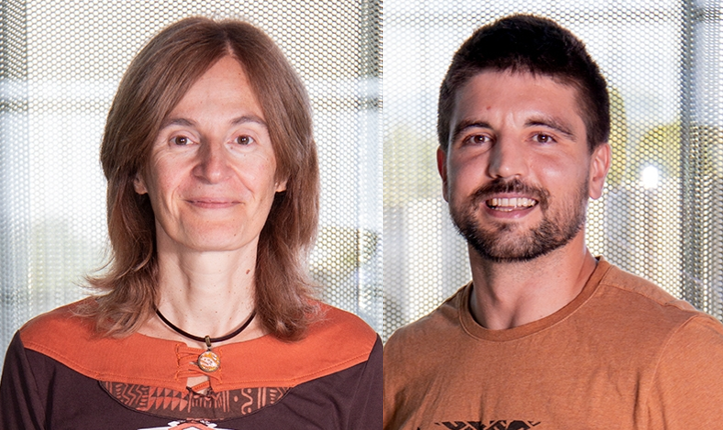

Compact thermal energy storage can be achieved with a large number of materials. To reduce costs, a high energy density of the storage material at optimal temperatures is desirable. The storage research group of the Spanish institute CIC energiGUNE has worked on different ways to optimize phase-change materials (PCMs) to increase the enthalpy and tailor working temperatures. We discussed their work with two CIC energiGUNE researchers: Stefania Doppiu and Angel Serrano (see photo). They are both involved in Task 67 on Compact Thermal Energy Storage Materials of the IEA Solar Heating and Cooling Programme. This international research group has put together an overview of ways to optimize phase change materials (PCMs).

Photo: CIC energiGUNE

Which goals are you pursuing with your overview of ways to optimize PCMs?

Stefania Doppiu: The idea is to give experts in material development an overview. The IEA SHC Task 67 is very well-placed to publish such an overview because the group brings together many researchers that are working on different approaches to optimize PCMs. Other scientists can benefit from this knowledge hub. We also have to emphasize that the Task 67 research group is working on an overview to optimize thermo-chemical materials (TCMs) for compact energy storage systems.

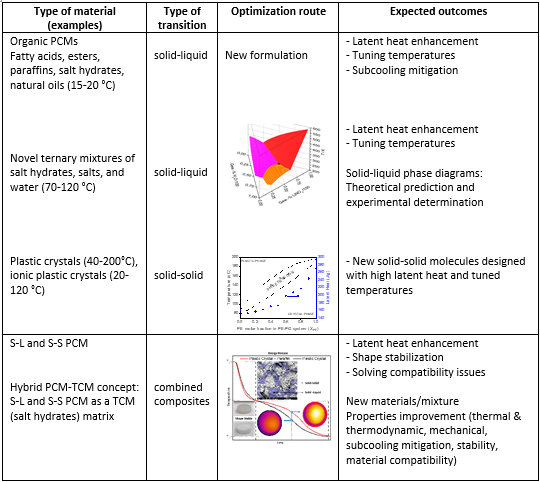

You have developed a table showing different optimization strategies (see table below). Which ones did you identify?

Doppiu: The first two lines apply to solid-liquid PCMs. The first line describes the preparation of new material compositions. Combining PCMs with different temperature levels of their transition phase, for example, allows good adaptation to specific applications.

In the second line of the table a three-dimensional solid-liquid phase diagram of mixtures of salts and hydrates is used. This chart indicates which components melt and solidify at a specific temperature, so that you can fine-tune the temperature of the mixture. If you combine two PCMs with different melting temperatures, the mixture will have a new melting temperature. It is a requirement for a cycle-resistant PCM that all the components of the mixture melt or solidify at a single temperature.

Examples of ways to optimize PCMs Source: IEA SHC Task 67

The third line of the PCM overview table highlights solid-solid PCMs. This is the focus of the research work of Angel Serrano. Can you explain this method of optimization?

Angel Serrano: Solid-solid PCMs have been known for some time, but there is growing interest and research focused on these materials. Unlike traditional PCMs, which absorb heat by changing from a solid to a liquid, solid-solid PCMs absorb heat by changing their crystalline structure while remaining solid. For example, the crystalline structure can change from tetragonal to face-centred cubic.

While these phase changes often involve very small energy gaps, we focus on materials with high enthalpies of transition. This is mainly due to the strong molecular forces that break and re-form during their phase transitions.

One clear advantage of solid-solid PCMs is that they remain solid, allowing heat transfer fluids to pass directly through the material without the need for a heat exchanger. This contrasts with solid-liquid PCMs, which usually require encapsulation. If the heat transfer fluid is compatible with the PCM material, the absence of a heat exchanger simplifies the system and reduces costs significantly. Considering that heat exchangers can account for up to 70 % of the compact storage tank cost, this presents a notable economic benefit.

Can you give an example of a material that you have examined?

Serrano: We have examined the properties of, for example, organic plastic crystals such as pentaerythritol (PE) and pentaglycerine (PG). These materials undergo reversible solid-solid phase transitions, offering high enthalpy values and adjustable transition temperatures. The binary PE:PG system allows us to adjust the discharge temperature steplessly between 78 °C and 185 °C, covering a temperature range that currently lacks sufficient phase change material options. The tailored system exhibits promising thermal characteristics surpassing other PCMs within the same temperature range.

What would be a worthwhile improvement factor here that would motivate you to develop a material mixture further?

Serrano: In this particular case, the stepless temperature adjustment capability allows us to address applications with very different temperature requirements by combining only two materials. This eliminates the need to find a specific material for each application and facilitates the development of a more “universal” system. In this case, more than seeking the improvement of a single parameter, our research aims to ensure that this temperature adjustment remains stable over multiple charge and discharge cycles and can be achieved in a simple and cost-effective manner.

When we focus on improving enthalpy, any improvement can be valuable as long as the cost of achieving it is justified by the resulting reduction in overall system storage costs and increased compactness of the system.

Task 67 will end this year, what can we expect as a final resource of your subtask within Task 67?

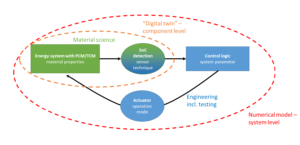

Doppiu: We are working on a guideline describing ways to optimize storage materials, but also to analyse the impact these improved materials will have when integrated into thermal energy storage systems. The critical point is how to assess the real impact of the improved material in the storage tank system. This approach is very new and not a lot of research has been done in this field.

If we succeed in describing the influencing factors, we can then critically assess much earlier in the materials research process whether a specific material will later lead to the desired efficiency improvements in the storage system. This is important because it could happen that we spend years trying to improve a new material mixture and in the end we discover that the impact on the storage tank system will be rather small.

We will publish a first version of this guideline at the end of Task 67 this year. We expect that there will be a new task on storage within the IEA SHC Programme and then we want to further develop the guideline.

Websites of organizations mentioned in this news article:

IEA SHC Programme: https://www.iea-shc.org/

IEA SHC Task 67 – Compact Thermal Energy Storage Materials: https://task67.iea-shc.org/

CIC energiGUNE: https://cicenergigune.com/en