Austria: Task 42 Meeting on Compact Thermal Energy Storage Systems

March 3, 2015

IEA-SHC Task 42, entitled Compact Thermal Energy Storage, has entered into its final year and will end in December 2015. In February 2015, 44 scientists met for the 13th Experts Task Meeting in Vienna, Austria, to discuss the characterisation and development of materials for latent heat storage systems. This included phase change materials (PCM) like paraffin and thermo-chemical materials (TCM), such as sodium hydroxide solutions or zeolites. During the three-day meeting, the task members also visited the cogeneration plant Simmering in Vienna. The photo shows them in front of two pressurised water tanks with a total volume of 11,000 m3. The tanks are charged and discharged with 145 GWh annually and are operated to decouple heat energy production from demand in the district heating network of Vienna.

IEA-SHC Task 42, entitled Compact Thermal Energy Storage, has entered into its final year and will end in December 2015. In February 2015, 44 scientists met for the 13th Experts Task Meeting in Vienna, Austria, to discuss the characterisation and development of materials for latent heat storage systems. This included phase change materials (PCM) like paraffin and thermo-chemical materials (TCM), such as sodium hydroxide solutions or zeolites. During the three-day meeting, the task members also visited the cogeneration plant Simmering in Vienna. The photo shows them in front of two pressurised water tanks with a total volume of 11,000 m3. The tanks are charged and discharged with 145 GWh annually and are operated to decouple heat energy production from demand in the district heating network of Vienna.Photo: Institute for Solar Technology SPF

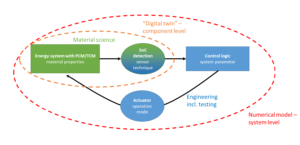

Task 42 of the IEA-SHC programme is also part of IEA programme Energy Conservation through Energy Storage (ECES) and listed as IEA-ECES Annex 29 there. The task combines the best of both worlds by bringing together material scientists from the ECES side and specialists on process engineering from the SHC programme.

Latent heat storage materials can capture large amounts of energy with no or very little change in temperature and therefore provide compact volumes with small energy losses. “It makes these materials a promising solution for seasonal heat storage,” says the task´s operating agent, Professor Matthias Rommel, Director of the Institute for Solar Technology, SPF, at the University of Applied Sciences, HSR, in Switzerland.

Long-term storage to meet heating demand in winter

For example, paraffin has a melting point of 55°C and a melting enthalpy of 53 kWh/m³. Water, as a comparison, can store 12 kWh/m³ at a temperature difference of 10 K. To achieve a heat density similar to paraffin, water needs to be heated by more than 40°C. But although latent materials themselves are a promising technology, there have been almost no commercial storage products available yet. Loading and unloading processes, as well as peripheral facilities reduce efficiency and increase costs.

Rommel is convinced that the effort put into latent heat storage systems will pay off in the long run. “Long-term storage of solar heat is the only answer to the question of how to meet heating demand in winter.” To continue the work, the participants would favour a follow-up project, and the IEA will make its decision by the end of the year.

Thermo-chemical storage: From lab to test applications

Sorption materials absorb energy when water is expelled and release energy when water is absorbed. But, actually, the sorption process requires steam, not water. Producing steam at low temperatures is a task for vacuum technology, which is costly and requires technical components that need space. Theoretically, TCM storage could store three to five times more energy at the same volume than water-based storage. In real-life application in pilot projects, the storage density has so far turned out to be lower than the one for water. “Experimental set-ups and vacuum technology still need a lot of space. Currently, system operation is also not reliable enough,” Rommel says. “This shows that there is still a lot of process improvement to be done.”

The goal of the Task 42 scientists is to define operating conditions and develop models which allow for a calculation of how much storage capacity would have to be in operation for a certain material. For example, capacity varies with certain boundary conditions, such as required temperature or steam pressure. With this model, the researchers intend to evaluate several TCMs and design new TCMs more systematically. The economic constraints of latent energy storage systems are being investigated as well.

The final results of IEA-SHC Task 42 will be presented at the SHC 2015 conference, which will be held in Istanbul, Turkey, from 2 to 4 December 2015.

More information: