Interactive learning at South Africa’s Solar Process Heat Training Week

September 24, 2025

The Solar Process Heat Training Week in mid-August 2025 near Pretoria, South Africa, offered a well-balanced mix of theory and practice. The four-day training was organized and hosted by SANEDI, the South African National Energy Development Institute, in cooperation with the IEA SHC Solar Academy. A total of 37 participants – including engineers, commercial renewable installers, energy auditors, and EPC contractors – took part in the program, which also featured a technical tour with site visits on the second training day (see photo).

Photo: Welcome Nukeri, SANEDI

The sessions on planning and project development of solar process heat systems, held on the third and fourth day, were led by Jonathan Koifman, Head of Channel Sales & Partner Development at TVP Solar. The Swiss company manufactures evacuated flat plate collectors and develops large-scale commercial solar heat plants. “Most questions by the participants were related to data collection and integration design. These were also the most important points of my lectures during the workshop, as in my experience these are the key elements for a successful SHIP project,” Koifman explained. He noted the participants’ strong motivation to deepen their knowledge of SHIP project development.

An example of Koifman’s interactive and practice-oriented approach during the training was a live poll he conducted with the participants. He asked them to decide at which insertion point they would integrate solar heat in the following case: “A food processing plant operates an 8-bar steam generator. Thirty percent of the steam is directed to a steam/water heat exchanger for an 85 °C clean-in-place (CIP) process.”

He offered three options:

- Preheating of boiler feedwater (45% of participants selected this option)

- Return blend on the CIP subloop (55% selected this option)

- Installation of a new low-pressure steam generator (no one selected this option)

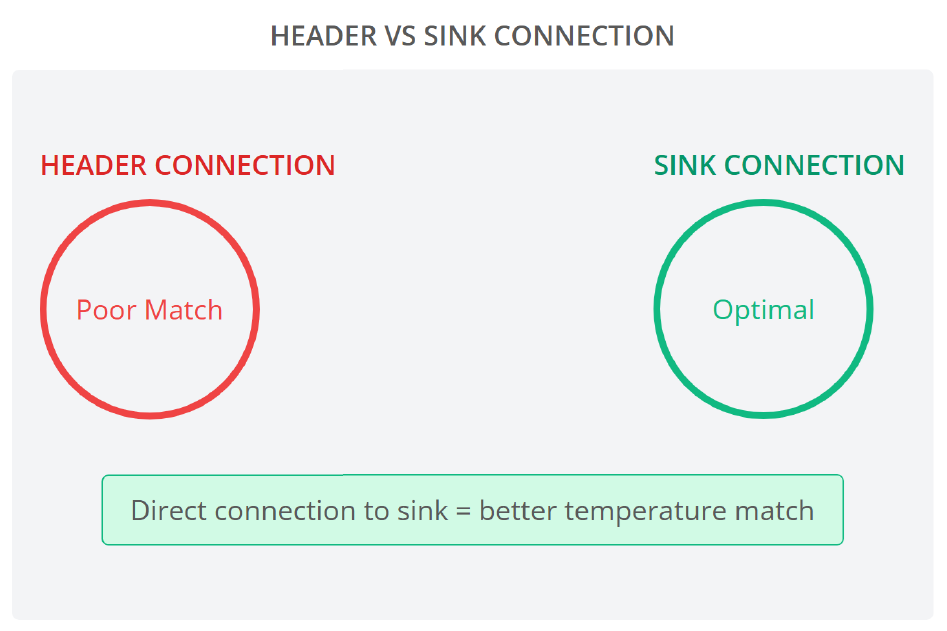

Koifman then presented the following scheme and explained: “It is critical to identify the correct heat sink, as the heat sink usually demands a more appropriate temperature to maximize solar contribution instead of preheating the steam line. This can make the difference between achieving 8% savings and up to 100% savings.”

What is the best place to inject heat from solar thermal? Source: TVP Solar

Koifman had two important main messages that he passed over during the training: First, SHIP implementation cannot be done in a silo – a network of project developers, auditors, integration specialists and installers needs to be in place in order to achieve successful SHIP projects. And second, SHIP projects take time. Generally more than three years from initial data collection to handover means that project developers have to have the working capital and capacity to last the course.

Women in solar heat: Nine female participants joined the SHIP training in South Africa among the 37 participants, but SANEDI plans to boost women’s participation in future trainings. Photo: Welcome Nukeri, SANEDI

Websites of or0ganisations mentioned in this news article:

IEA SHC Solar Academy: https://www.iea-shc.org/solar-academy

SANEDI: https://sanedi.org.za/

TVP Solar: https://www.tvpsolar.com/