High solar heat fraction solutions supported by heat pumps

October 27, 2024

The German heating technology manufacturer Viessmann Climate Solutions has been part of Carrier Global, the largest US manufacturer of air conditioning systems, since March 2023. This merger is now also beginning to bear fruit in Germany. The German town of Bracht is not only benefiting from a turnkey solar heat system from Viessmann, but the company is also supplying two Carrier Aquaforce heat pumps for the heating centre, each with a rated thermal output of 624 kWth. These will use heat from the newly installed seasonal storage tank, cooling it to 30 °C by spring so that more solar heat can be stored in the summer. Previously, the largest high-temperature heat pump in Viessmann’s portfolio was the Vitocal 350 HT pro, rated at 352 kWth. A unit from this series has been in operation at Flavex, Germany, a company specializing in natural extracts, since spring 2024.

Screenshot from: https://register.pep-ecopassport.org/pep/consult

“The Carrier heat pump will serve as an efficiency booster in Bracht. If the temperature in the storage tank is too low to provide the 85 °C flow temperature required by the heating network, especially in the winter months, the heat pump can raise the temperature level,” explained Marco Ohme, Head of District Heating Solutions at Viessmann.

The heat pump draws heat from the 14-metre-deep storage tank, preferably from the central area. This ensures that the solar collector array can be supplied with colder water via the return flow of the collector circuit. This increases the efficiency of the collectors and their yield.

If no heat pumps are used, the minimum storage temperature is limited to the return temperature of the heating network – in the very optimistic case, for example, to 45 °C. “Discharging the storage tank to 20 Kelvin lower increases the storage capacity from 1.1 GWh to 1.7 GWh. The seasonal storage tank can therefore be dimensioned 35 % smaller, which saves considerable costs,” explained Paul Volk, Researcher at the University of Kassel, Germany.

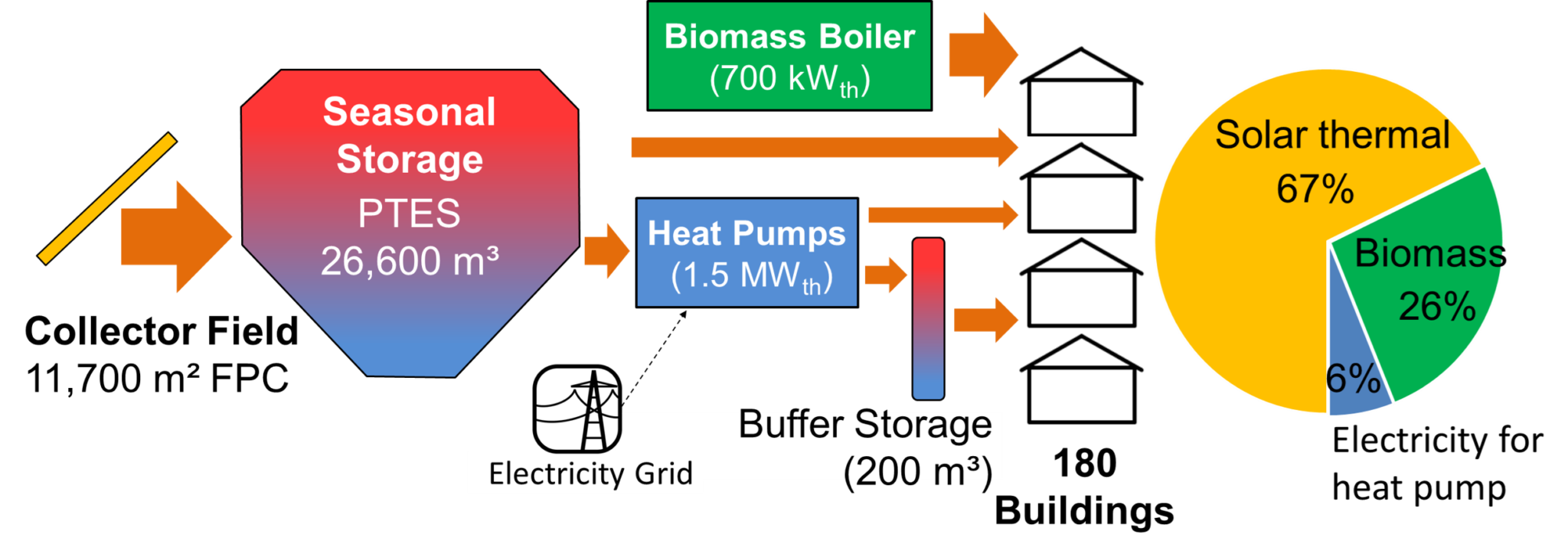

Overview of renewable heating supply system in the village of Bracht, Germany

Source: University of Kassel

180 households in Bracht have already decided to be connected to the new district heating network in the village. 70% of their annual heating requirements will be covered by the collector system with seasonal storage. This will bring the village a big step closer to its goal of becoming a climate-neutral village by 2025. The Carrier heat pumps are expected to provide around 10 % of the heat supply each year. The aim of the design was that the biomass boiler will cover less than a quarter of the total heat requirement.

The project volume is around EUR 16.5 million, of which more than half (EUR 10.5 million) is the estimated cost of the heat energy supply system and the district heating network, as stated in a Viessmann press release dated 12 July 2024.

Seasonal storage in Bracht: The Danish company Ramboll carried out the feasibility study and developed the construction of the cover, while the black geomembranes were supplied by Solmax, Germany. Photo: Ruwen Erler

The University of Kassel supported the planning of the system in Bracht with a prefeasibility study. The researchers calculated levelized cost of heat before funding of 21.3 EUR/MWh based on net costs in the year 2022. “Renewable heating networks with high solar fractions can be economically viable”, concluded the researchers in a poster presented in August at Eurosun 2024 in Cyprus.

As part of the investigations by the University of Kassel into the decarbonization of the heat supply in Bracht, comprehensive insulation of the houses, 50% of which are more than 40 years old, was also considered as an option. Although the costs are largely identical, the difference lies in the fact that it would take decades to refurbish each house individually. In contrast, the scientists concluded that solar heating would reduce CO₂ emissions by 98% within just two years.

A long-standing PV system has now been supplemented by a collector field (centre of the picture), which supplies process heat at 80 °C for the company Flavex Naturextrakte Photo: Flavex Naturextrakte

Flavex Naturextrakte has been generating its own electricity from PV systems for many years and also obtains 100 % green electricity from external sources. The company has now taken important steps to cover its large heating and cooling requirements sustainably as well. These requirements arise because the CO2 extraction process requires gaseous and liquid carbon dioxide. To achieve these conditions, the production facilities have to be heated and cooled in three-shift operation

This spring, Viessmann installed a 288 m2 vacuum tube collector field at Flavex and supplied a heat pump of the type Vitocal 350-HT Pro, both of which feed into Flavex’s hot water network in parallel. The Vitocal unit utilizes the 30 to 35 °C waste heat from the propane gas refrigeration system as a heat source. In order to be able to operate the Vitocal unit as flexibly as possible, there is a storage tank on both the source side and the sink side. The regenerative heat supply system was planned by Famis, an E.ON subsidiary.

“The system was calculated in advance with a COP of 4.0. This fluctuates between 75 and 95 °C due to different process heat temperatures,” explained Jan Fehlhaber, Sales Manager at Famis. Depending on the temperature provided and required, the heat from the solar collector field is utilized directly as process heat or is used to preheat the secondary side of the heat pump. On an annual average, solar coverage of approximately 40 % is possible.

| Client | Citizens cooperation Rauschenberg-Bracht, Germany | FLAVEX Naturextrakte, Saarland, Germany |

| Manufacturer of heat pump | Carrier Global, USA | Viessmann Climate Solutions, Germany |

| Product type | Carrier Aquaforce 61XWHH-ZE | Vitocal 352-AHT 096 |

| Type of heat pump | Water-water heat pump | Water-water heat pump |

| Maximum thermal capacity | Two units of 624 kWth each | One unit of 142 kWth |

| Type of compressor | Twin-rotor screw compressors with a variable capacity valve | Piston compressor |

| Which application is the delivered heat used for? | Providing heat for district heating | Up to 85 °C process heat |

| How many stages does the heat pump have? | Double stage | Double stage |

| Type of heat source for heat pump and temperature level of heat source | Heat from the central part of the seasonal storage | Waste heat from cooling circuit at 30 to 35 °C |

| Type of heat and temperature level of delivered heat | Heat up to 85 °C for the district heating field | 75 to 95 °C hot water |

| Type of refrigerant | R-1234ze | R1234ze |

| Type of collector | Vitosol 100-F XF13 (flat plate collector | Vitosol 200-T Typ SPX (vacuum tube collector) |

| COP | 4.7 | ~4 (simulations in the planning phase) |

| Gross area of the collector field | 11,638 m² | 288 m2 |

| Maximum thermal capacity of collector field | 8.2 MWth | 201 kWth |

| Volume of seasonal storage | 27.000 m³ | 15,000 litres |

| Type of storage | Pit heat storage tank | Daily storage tank |

| Solar fraction | 70 % | 40 % |

| Commissioning date of first part of district heating system | Planned for spring 2025 | Spring 2024 |

Technical and financial data for two regenerative energy supply systems that combine a collector field and a heat pump and achieve a high solar heat fraction. Source: Viessmann Climate Solutions

Websites of organizations mentioned in this news article:

Citizens cooperation Bracht: https://www.solarwaerme-bracht.de/

Flavex Naturextrakte: https://www.flavex.com/en/

Viessmann Climate Solutions: https://www.viessmann.com/

Famis GmbH: https://www.famis-gmbh.de/dienstleistungen/startseite