Australia: Good Funding for Solar Process Heat, but Little Trust by Industry

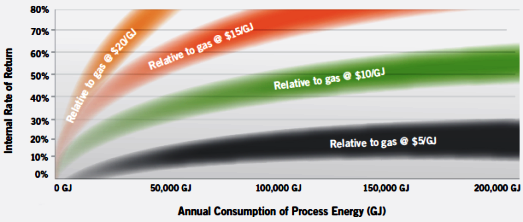

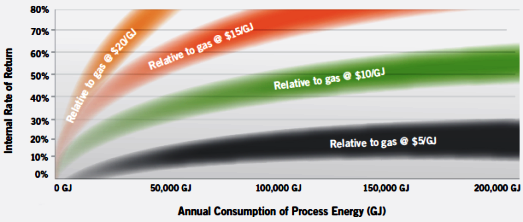

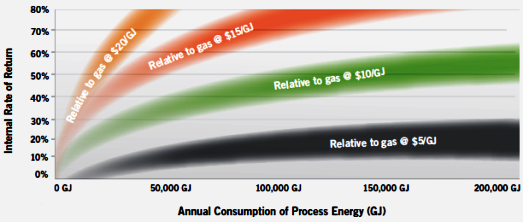

Australia’s energy policy has been in the international press mostly for its shift back toward coal under the former Prime Minister Tony Abbott. However, Jeremy Osborne, Director of Energy Analysis & Engineering, said in an interview with solarthermalworld.org that Australia did have a “supportive government despite all the news”. Since July 2015, renewables for industrial processes has been one of the Australian Renewable Energy Agency’s (ARENA) investment priorities, which includes solar process heat. ARENA also published the report Renewable Energy Options for Australian Industrial Gas Users in September 2015, emphasising that lower-temperature process heat systems at around 100 °C are most “prospective at present” (see the attached document). Positive Internal Rates of Return (IRR) are achieved with gas prices above Australian Dollar (AUD) 5 per gigajoules (GJ). According to the report, the wholesale price for gas was between 6 and 8 AUD/GJ in 2014 and is expected to rise to between 9 and 12 AUD/GJ before the end of the decade.

Australia’s energy policy has been in the international press mostly for its shift back toward coal under the former Prime Minister Tony Abbott. However, Jeremy Osborne, Director of Energy Analysis & Engineering, said in an interview with solarthermalworld.org that Australia did have a “supportive government despite all the news”. Since July 2015, renewables for industrial processes has been one of the Australian Renewable Energy Agency’s (ARENA) investment priorities, which includes solar process heat. ARENA also published the report Renewable Energy Options for Australian Industrial Gas Users in September 2015, emphasising that lower-temperature process heat systems at around 100 °C are most “prospective at present” (see the attached document). Positive Internal Rates of Return (IRR) are achieved with gas prices above Australian Dollar (AUD) 5 per gigajoules (GJ). According to the report, the wholesale price for gas was between 6 and 8 AUD/GJ in 2014 and is expected to rise to between 9 and 12 AUD/GJ before the end of the decade. Chart: ARENA

Since July 2015, renewable energy for industrial processes has been one of ARENA’s investment focus areas under the agency’s Advancing Renewables Program (ARP). The ARP supports development, demonstration and pre-commercial deployment projects that have the potential to lower the cost and increase the use of renewable energy technologies in Australia over the long term.

Few solar process heat projects in Australia so far

So far, there have been few solar process heat projects across Australia, despite the country having some of the most abundant solar resources on the planet. According to the ARENA website, there is still no commercial-scale solar process heat project which received funding from the agency.

Although Australia has cheap gas, there is significant potential for solar process heat. About 20 % of the industrial gas used for heat generation is consumed in sectors such as food, pulp and paper, and dairy production. Those sectors pay prices similar to retail prices for their gas, and most of the energy used for these applications is consumed at less than 250 °C. Australia also has around 2,000 manufacturers that use approximately 400,000,000 GJ of gas every year to provide heat for industrial processes such as producing steam, drying, heating ovens and as chemical feedstock.

ARENA CEO Ivor Frischknecht said industrial energy use accounted for about 40 % of Australia’s total energy use, which is about two times commercial and residential consumption combined. “Natural gas is the predominant fuel for industry, where much of it is used for process heating. So we’re also looking at thermal energy now as a potential alternative,” Frischknecht said.

Increase industry confidence and understanding in solar process heat

Osborne regards a lack of knowledge and trust in solar thermal applications as the industry’s main bottleneck. ARENA is making efforts to change this. The ARENA-funded report from September addresses investors and presents six case studies of solar thermal projects, among them are two from Australia: 1,500 m² of unglazed collectors for pool heating at the Australian Institute for Sport in Canberra, a system which has been in operation since 2011, and 100 vacuum tube collectors (284 m² of aperture area) at the De Bortoli winery in New South Wales, in operation since 2013. The report also illustrates the investment and return rates of renewable process heat, depending on gas price, project size and temperature – for example, the Levelised Cost of Energy (LCOE) of 200 °C of solar thermal heat equals the cost of an existing gas boiler at 15 AUD/GJ, based on a yearly heat production of around 50,000 GJ (see figure 14, page 23 in the report).

Over the past six months, ARENA has also organised four workshops on solar process heat across the country to provide industry end-users with an understanding of what renewable energy technologies could be used for industrial process heating and the benefits that are possible. At these workshops Christoph Brunner of International Energy Agency’s Solar Heating and Cooling Task 49 (IEA-SHC Task 49) spoke about the worldwide uptake of solar thermal process heat, Andreas Werner, head of an Austrian Heineken brewery, talked about the shift from a 100 % dependency on natural gas toward 100 % renewables, and Peter Badstue Jensen from Aalborg CSP presented an Australian solar thermal project in Port Augusta, South Australia, which provides process heat for greenhouses, electrical power to run the desalination plant and energy for other applications.

In total, ARENA has committed AUD 15.5 million to projects with a total value of AUD 35 million that involve research and development of how renewable energy technologies can provide alternatives to fossil fuels for industrial process heating applications. The agency sees supporting these kinds of projects as a critical way to increase industry confidence and understanding in renewable energy.

Frischknecht said one example was ARENA providing University of Adelaide with AUD 4.5 million to investigate if solar thermal energy can be integrated into metals manufacturer Alcoa’s alumina refining process. “This is about turning bauxite into alumina. Aluminium refining and smelting is obviously big industry in Australia and it uses a huge amount of heat,” Frischknecht said. “The AUD 15 million project is exploring options that use solar thermal to generate that heat, as opposed to vast amounts of gas or coal.”

Two-step application process

Within the subsidy scheme for renewables for industrial processes there is no strict limit for a grant amount per project; ARENA decides on a case to case basis and seeks to fund the best projects and maximise value from taxpayer dollars. Installations valued at more than AUD $500,000 may require additional approval processes, whereas projects above AUD $50 million require ministerial approval.

Companies seeking ARENA funding support should first check with the agency to gauge whether its project meets requirements and is undertaking something sufficiently innovative and novel that will decrease the cost of renewable energy. ARENA will provide advice on whether the project could help achieve its goals. The goals of its ‘Renewables for industrial processes’ priority include:

- Displace fossil fuels in industrial processes, particularly the use of gas to produce thermal energy;

- Establish the economic benefits possible from renewable energy use by reducing exposure to future volatility in energy prices;

- Reduce the technical and commercial risks associated with renewable energy deployment.

If the project is a good fit with ARENA’s investment priorities and the objectives and outcomes of the ARP, the applicant will be encouraged by ARENA to submit an expression of interest, which, if successful will be followed by a more detailed full application. A funding agreement is then negotiated between ARENA and the applicant.

ARENA provides grant funding for interesting and innovative renewable energy projects with the aim of extracting the knowledge gained, increasing confidence amongst the energy and finance industries, overcoming barriers and decreasing risk to stimulate the next wave of new and innovative projects and make renewable energy more affordable. Grants are typically paid in arrears based on milestones reached during the project.

More information:

ARENA: arena.gov.au