Storing high-temperature heat for commercial clients in Denmark, Norway and Belgium

The level of commercialization was one of the key questions we asked all high-temperature storage solution providers in the survey carried out at the beginning of 2024. Among the 31 companies in the overview are six companies that have already put commercial storage into operation: Brenmiller (Israel), Eco-Tech Ceram (France), Energynest and Kyoto Group (both Norway), Polar Night Energy (Finland), and Rondo Energy (USA). Other companies reported that their first commercial plant is currently under construction, for example Luminium (Germany). In this article we describe the commercial systems for storing high-temperature heat for the two Norwegian companies. Both companies predict increasing demand for their solutions. The photo shows the team at Energynest “trying” to lift a ThermalBattery module. The modules are sent to the customer uninsulated, where they are stacked and connected together and then insulated as a complete system. You can find the entire results of the study on high temperature storage solution providers here.

Photo: Energynest

In 2023 Energynest put its first two commercial systems with thermal batteries into operation. The batteries consist of a bundle of concrete tubes into which the heat exchangers are embedded. In both of the new systems, storage tanks are charged with heat and provide steam or hot thermal oil for the customers’ operations.

Since January 2023 the fertilizer manufacturer Yara in Norway has been operating a 4 MWh storage system. The storage has already gone through more than 4,000 cycles over the past year. “At Yara our storage is directly connected to the company’s steam network and is therefore charged and discharged almost every second, depending on the process for producing fertilizer on site”, explained Christian Thiel, Chief Executive Officer of Energynest. “We store the thermal energy that is not generated in line with demand and then deliver steam during short demand peaks. The system thus increases energy efficiency and offers flexibility.” At Yara, the storage is loaded using steam at 272 °C and 34 bar directly from the on-site steam grid and delivers dry steam at 189 °C and 5 bar to the client’s steam network.

The second ThermalBattery has been running at the adhesive manufacturer Avery Dennison in Turnhout Belgium since summer 2023.

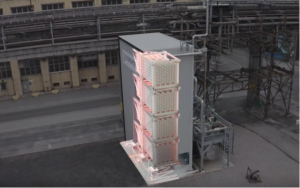

Figure 1: ThermalBattery at Yara. Four modules are stacked. The illustration shows the charging process from the back. The steam drum is installed behind the storage and connected to the client’s steam network. Illustration: Energynest

A ThermalBattery unit has a maximum storage capacity of 1 to 2 MWh depending on the temperature difference during operation, energy density and charging and discharging variables. At Avery Dennison, six modules are stacked on top of each other. Energynest states the total storage capacity there is 5 MWh with charging/discharging temperatures of 380 and 310 °C respectively. The 2.4 MW parabolic trough collector field is expected to deliver 2.7 GWh of solar heat over the year, which is 6 MWh per day in average.

Energynest is currently building up an “enormously large project pipeline,” as Thiel emphasized: “We have received a lot of inquiries since the Ukraine war and the gas price shock.”

The company has existed since 2011. It has 42 employees in Norway, Germany, Spain and the Netherlands. Energynest is well-financed by a financial boost of EUR 110 million in 2021 from the infrastructure fund Infracapital.

| Storage tank provider | Kyoto Group | Energynest | Energynest |

| Client name | Aalborg Forsyning, Denmark | Fertilizer manufacturer Yara, Norway | Avery Dennison, Belgium |

| Name of storage | Heatcube | ThermalBattery | ThermalBattery |

| Type of storage / storage material | Molten salt storage / molten salt | Solid-media storage / concrete tubes called Heatcrete | Solid-media storage / concrete tubes called Heatcrete |

| Operation mode of storage | Power-to-heat | Heat-to-heat (steam) | Heat-to-heat (thermal oil) |

| Maximum storage capacity | 18 MWh | 4 MWh (4 modules) | 5 MWh (six modules) |

| Which application is the stored heat is used for? | Delivering heat to the Aalborg district heating system | Steam network of client for fertilizer production | Operation of drying ovens during

coating process |

| Range of temperature for operating storage | Stored at up to 415 °C, district heating grid at 70 to 95 °C | Charging at 272 °C (34 bar) / discharging at 189 °C (5 bar, dry steam) | Charging at 380 °C / discharging at 310 °C |

| Date of commissioning | August 2023 | December 2022 | August 2023 |

Key figures for the commercial medium/high-temperature storage projects of the two Norwegian companies Energynest and Kyoto Group. In the ThermalBattery, U-shaped carbon steel heat exchange tubes are cast into special concrete named Heatcrete. There is no standardized method to calculate the heat capacity of a high-temperature storage system and therefore numbers reported by each provider may be inconsistent or vary based on what calculation has been used. On this aspect, please also read the interview with storage expert Annelies Vandersickel.

Source: companies’ information

Kyoto Group: Power-to-heat storage ramp-up to 5 MW in only 90 seconds

Figure 2: First commercial demonstration of a Heatcube storage system at Norbis Park in Denmark. It was manufactured in Spain, shipped to Denmark, and then assembled on site. Photo: Kyoto Group

Kyoto Group commissioned its first commercial demonstration plant at Norbis Park, formerly known as Nordjyllandsværket, in Denmark. This Heatcube at Norbis Park comprises several tanks filled with molten salt (refer to Figure 3). The 18 MWh system is charged using electricity from the grid or surplus renewable power when available. It stores thermal energy in molten salt up to 415°C and delivers heat between 70°C and 95°C to the local district heating system. Aalborg Forsyning, a utility that is part of the Aalborg municipality, owns and operates the storage system.

According to Kyoto Group, the Heatcube at Norbis Park performed well over the first six months. It successfully passed the power market test to provide flexibility services to the Danish electricity market in the DK1 grid area, as announced in a press release in November 2023. “Heatcube achieved a smooth and dependable ramp-up of the heater from 0 MW to 5 MW in 90 seconds, well within the requirements for balancing market participation”, explained Tim de Haas, Chief Commercial Officer of Kyoto Group. “Now, our industrial customers have access to the reserve and intraday electricity market, ensuring access to very cheap electricity, which further improves their business case.”

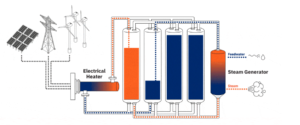

Figure 3: Simultaneous charging and discharging: The molten-salt-filled tanks are charged via the electrical heater from the left and discharged with water via a steam generator on the right. The molten salt needs to be kept constantly in the liquid phase above 190°C.

Graphic: Kyoto Group

Kyoto envisions a continuously growing commercial pipeline. Among the achievements in 2023 was securing an order worth EUR 6.4 million for the first full-scale commercial Heatcube project, serving as power-to-heat for the Hungarian food ingredient producer KALL Ingredients. The partners, including Kyotherm from France, Energiabörze from Hungary and Kyoto, have established a Hungarian legal entity (SPV). This entity has entered into a heat-as-a-service agreement with KALL, with Kyotherm as the majority investor and Energiabörze as the minority investor. The SPV has purchased the Heatcube from Kyoto Group, which will deliver the turnkey thermal storage unit with a maximum capacity of 56 MWh to KALL Ingredients. The storage will provide steam for corn processing at around 200 °C and operate as an asset in the flexibility market.

Kyoto envisions a continuously growing commercial pipeline

In December 2023, Kyoto signed a term sheet and initiated an engineering study for a Heatcube at the paper and packaging manufacturer Klingele’s site in Werne, Germany. Klingele aims to reduce CO2 emissions at its Werne plant by 55 % by 2030. The planned Heatcube will have a storage capacity of 48 MWh in power-to-heat, replacing current heat energy from natural gas.

Furthermore, in 2023, Kyoto announced that it had increased the guaranteed round-trip efficiency (RTE) of the Heatcube from 90 % to 93 %. Kyoto measures the RTE as the total energy efficiency over a full charge and discharge cycle directly behind each other, taking into account all the losses from components such as medium-voltage transformers, electrical heaters, tanks, pipes, valves, pumps and steam generators. According to the company’s information, this increase in efficiency is guaranteed based on numerous simulations, validated by tests at the unit at Norbis Park, and detailed calculations rooted in Heatcube’s mature design.

Additionally, strategic investors joined Kyoto Group in 2023. Notably, Kyoto secured a EUR 3 million investment from the Spanish utility company Iberdrola and a EUR 3.5 million investment from the British manufacturer Spirax-Sarco Engineering. Consequently, Iberdrola now holds a 12.8 % stake in the company and Spirax-Sarco Engineering holds a 15 % stake. Kyoto Group is listed on Euronext Growth Oslo.

Figure 4: The tanks for the Heatcube at Norbis Park in the factory hall. The vessels were placed vertically and filled with salt on site in Denmark. Photo: Kyoto Group

This news article was written in cooperation with Alejandro Diego Rosell, freelance journalist from Spain.

Websites of organizations mentioned in this article:

Energynest: https://energy-nest.com/

Kyoto Group: https://www.kyotogroup.no/

Norbis Park: https://investinaalborg.dk/norbis-new-green-test-center-in-aalborg/

Yara: https://www.yara.com/

Avery Dennison: https://www.averydennison.com/en/home.html