PVT NEXUS: Dedicated research network set to advance PVT innovation

August 12, 2025

The European photovoltaic-thermal PVT market is picking up speed. Consequently, the number of PVT manufacturers is also growing, particularly in key countries such as Germany, Switzerland, and the Netherlands. To strengthen research capacities in this evolving field, the European project PVT4EU is initiating the creation of a dedicated research network focused on PVT technologies and systems. This network will officially launch during an online workshop on Wednesday, August 27, from 10:00 AM to 4:30 PM CEST. The photo shows the PVT4EU consortium under the leadership of the Swedish company MG Sustainable Engineering AB. Photo: PVT4EU

“The planned research network called PVT NEXUS aims to cultivate a new generation of researchers equipped to drive innovation, accelerate market deployment, and deepen our understanding of PVT systems”, said Maryam Shalaby, Project Manager at MG Sustainable Engineering. The network is designed to complement and enhance existing initiatives, such as the IEA SHC Task 73 on PVT Heating Systems, by fostering interdisciplinary collaboration, supporting knowledge exchange, and boosting the visibility of early-stage research.

The workshop titled Modelling and Experimentation of PVT Technologies will address key topics in the development of PVT systems, including system integration and applications, modeling techniques, experimental testing, as well as future trends and challenges. The workshop programme and registration link can be found here.

Development of PVT collector prototypes

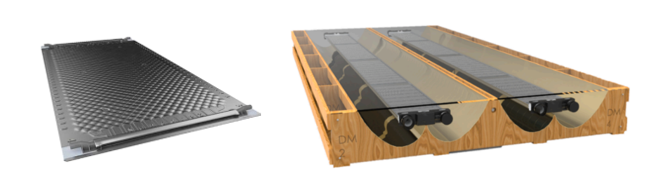

PVT4EU has started in October 2023 and will end in September 2026. One of the key activities is the develoipment of two new PVT prototypes, developed and tested under real-world Nordic and Southern European conditions (see graphics below).

The first prototype is the PVT-SP collector, originally developed as a polymeric heat recovery media for HVAC applications, is now being repurposed as a flat plate absorber retrofit for PV panels. This repurposing focuses on optimizing thermal performance for low-grade heat applications, with particular interest in heat pump integration, pool heating, and other potential uses.

Although counterintuitive, the design goal for the PVT-SP collector is not to maximize thermal retention but to promote ambient thermal losses. This approach enables the collector to function as an effective low-temperature heat source for heat pump systems exchanging heat with the air – particularly advantageous at low irradiance levels, where encouraging losses proves more beneficial than minimizing them. For applications that do not involve heat pump integration, this design trade-off can be mitigated during commissioning by adding insulation as needed.

The second prototype is a double CPC collector, called PVT-MG, designed for high-temperature applications such as solar heat for industrial processes and domestic hot water production. In this case, the objective is to maximize thermal energy capture and retention, ensuring stable performance specially at elevated operating temperatures up to 140 ºC. The collector features two paralell aluminium receivers, with elyptical flow channels.

Schemes of the two protoypes: PVT-SP on the left and PVT-MG on the right Graphics: PVT4EU

Websites of organisations mentioned in this news article:

PVT4EU: https://pvt4eu.eu/

TASK 73: https://task73.iea-shc.org/

MG Sustainable Engineering: https://mgsust.com/

Workshop Modelling and Experimentation of PVT technologies: : https://www.linkedin.com/events/modellingandexperimentationofpv7345739165906448386/about/