Industrial heat decarbonization: political vision versus market reality

October 23, 2025

How can research and innovation tackle the urgent challenges of industrial heat decarbonization? This was the central question explored during the Research on Solar Heat for Industrial Processes in the Nordics workshop, held in early September. The one-day event was organized by the Swedish company MG Sustainable Engineering in collaboration with the Technical University of Denmark (DTU). The organisers invited leading experts from the IEA Solar Heating and Cooling Programme for a series of presentations and a roundtable discussion. Key insights were shared on topics such as standardization and electrification in solar process heat projects. Notable contributions came from Joakim Byström, CEO of Absolicon Solar Collectors, Sweden, and Miguel Herrador, R&D and Spain Office Manager at Aalborg CSP, Denmark. The photo captures the panel discussion, moderated by Juan Pablo Santana, Project Manager at MG Sustainable Engineering and PhD student in Energy Systems at the University of Gävle, Sweden. The recording of the workshop is available online.

Source: Screenshot of the recording during the workshop

To begin the discussion, the moderator Santana referenced key insights from the Technology Position Paper published in January 2024 by IEA SHC Task 64 on Solar Process Heat (SHIP): “The task identified high efficiency and good return on investment as key strengths of SHIP plants, but also noted high capital expenditure (CAPEX) and system complexity as significant weaknesses. More critically, SHIP is often perceived as a high-risk investment, and the growing industrial shift toward electrification was highlighted as a major challenge.”

Santana then invited the industry representatives during the round table of the webinar to share their experiences in addressing these challenges during SHIP project development.

Herrador: Today, every project we develop requires many hours of engineering just to define the overall concept – highlighting a clear lack of standardization. Our approach has been to build a portfolio of pre-designed solutions in various sizes but within certain fixed parameters similar to what we implemented in our heat pump projects. For example, at Hillerød cistrict cooling and heating plant, the total heating and cooling demand from our client (10 MWth) was split into three systems, with 1.2 MWth cooling and 2 MWth heating units. This means, when an industrial client for example requests a 9 MWth solar heat plant, we could offer him standard configurations based on two balance of plant with 5MWth each, adapting to an existing standard solution. It will result in a slightly larger plant than the client originally requested. The client will, however, benefits in many ways when adapting these standard designs, including shorter delivery time, optimized CAPEX and levelized cost of heat, higher quality and reduced OPEX, as well as the assurance of a proven, reliable solution.

Santana noted that the easiest SHIP solution is often not the most efficient, while the most efficient option may be perceived as too risky or too broad for industrial clients to accept. He asked whether long-term profitability is a decisive factor for industrial clients, or if they tend to focus solely on short-term payback?

Byström: Clients are primarily focused on achieving the lowest cost per megawatt-hour of heat. What we often encounter is that when we present a profitable solar thermal installation covering 20 to 30 % of their heat demand, they consider it insufficient – they want a solution that covers 100 %. However, when we propose a fully renewable setup using heat pumps in different levels and storages, they reject it due to its complexity and cost.

Industrial clients envision a solution that is both highly profitable and capable of covering a large share of their heat demand with solar – but such a solution simply doesn’t exist today.

We’ve developed around 160 different project proposals and design studies, and none of them have been realized purely on a commercial basis. For the pilot plants we’ve built, we’ve either profited from public grants or put money in directly from Absolicon to show case different applications.

A 460 kW parabolic trough collector field from Absolicon has been installed at the Birra Peroni brewery in southern Italy. The system produces pressurized water, which is either converted into steam via a steam compressor and fed into the brewery’s 156 °C steam network, or used directly at 82 °C for the bottle-washing station. A 2 MWh pressurized hot water storage tank enables solar steam supply even during nighttime operations. Photo: Absolicon

Santana summarized that standardization has been one of the central topics of the workshop particularly for bringing down costs. One question remains according to Santana. “How do we make standardization happen and who should lead the effort, industry or academia or a joint initiative?

Herrador: Standardization is essential, but it must be driven by solar technology providers. We understand how to reduce CAPEX and how to design systems that are easy to build and operate. Let me give an example: we participated in an R&D EU-funded project where the plant was designed by a university. Their design was highly detailed – every pipe was specified with exact characteristics and diameters. However, instead of sourcing seven or eight different types of pipes, we proposed a more standardized design using just two sizes: small and medium. While this alternative may have slightly higher material costs, it significantly simplifies manufacturing and installation.

Our strategy – one that has proven very successful – is to involve our manufacturing team at our workshop in Sevilla from the very beginning of the project development phase. Their early input helps identify practical improvements and ensures the final design is optimized for real-world implementation.

Santana noted that electrification has become a prominent buzzword in the current industrial decarbonization landscape. In particular, policymakers often appear to believe that the energy transition can be achieved simply by electrifying everything. He posed the question: Are heat pumps considered the main competitor to solar process heat, or can these technologies complement each other and work hand in hand?

Byström: It’s important to understand that very few high-temperature heat pumps are actually being installed today. So, while they aren’t real competitors in the current market, they compete about the attention of the buyer. Business leaders often imagine that, just like a residential heat pump can provide heating and hot water from the outside air, the same principle can be applied to generate steam for a factory.

However, in our SHIP projects, we’ve found that integrating heat pumps has often proven too costly to meet the industry’s typical payback expectations.. From my perspective, heat pumps receive disproportionate attention, considering they are very expensive machines.

I want to point out that a good payback time in industry is two to three years, and this is very difficult to reach with a renewable energy project.

Politicians often envision electrification being achieved through electric boilers, heat pumps, and energy storage systems – but in reality, very little of this is actually being built.

This mindset partly stems from a fundamental misunderstanding of electricity pricing. Electricity is often said to be cheap, but that’s only if you consider the spot price at certain times of the day. What’s frequently overlooked is the cost of the grid – and the grid is very expensive. For example, in Sweden, grid connection fees are higher than the electricity price itself. On top of that, you have to include taxes and levies.

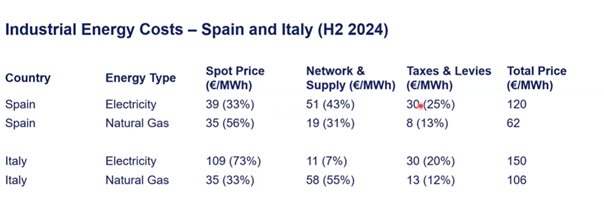

We’ve analyzed industrial energy costs in countries like Spain and Italy (see table below). Even when the spot price is zero, additional costs for electricity supply can still reach 79 EUR/MWh in Spain and 41 EUR/MWh in Italy. That said, verifying these figures is difficult, as companies rarely disclose their full energy bills.

Ultimately, this is an important learning that you can’t simply compare spot prices for electricity when evaluating them against direct renewable heat technologies like solar thermal or geothermal.

Industrial energy costs in Spain and in Italy in the second half of 2024 based on public available data and estimations made by Absolicon Solar Collector

Website of organisations mentioned in this news article:

IEA SHC Programme: https://www.iea-shc.org/

IEA SHC Task 64 on Solar Process Heat: https://task64.iea-shc.org/

Absolicon Solar Collectors: https://www.absolicon.com/

Aalborg CSP: https://www.aalborgcsp.de/