Growing production capacities of PVT collectors in Europe

February 1, 2024

European PVT manufacturers are anticipating strong growth in demand and expanding their factories. In November 2023 Abora Solar from Spain inaugurated its extended factory in Zaragoza, which has a capacity of 200,000 units per year, totalling 80 MWel. Sunmaxx PVT is building a PVT production plant in Saxony, eastern Germany, which has the capacity to produce 120,000 units per year with 50 MWel in total. Other established PVT manufacturers have also announced substantial production capacities. It will be interesting to see which producer will manage to utilize its manufacturing capacity in the coming years, as the market is still small. In 2022 (latest market data available), PVT modules with an electrical output of only 16 MWel were sold in Europe according to the most recent Solar Heat Worldwide report. The photo shows absorber production at the Dualsun factory in France.

Photo: Dualsun

Abora Solar: Optimizing and increasing production volumes

The greatly increased production capacity of the Abora Solar factory is based on two factors according to Alejandro del Amo, Founder and Managing Director. On the one hand, the existing production line has been optimized, resulting in an increased production volume of 180,000 collectors per year – up from 100,000 previously. On the other hand, Abora has installed an additional production line for a new type of PVT collector, which will come onto the market in 2025. The module is called “SHE” which stands for Solar Heat and Electricity. “We expect a doubling of sales year-by-year,” said del Amo and confirmed that they sold 25,000 m2 of PVT collectors in 2023.

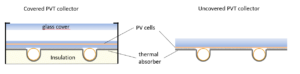

Abora Solar was founded in summer 2017 and is one of the few manufacturers of covered PVT collectors in Europe (see scheme below). The other two manufacturers of covered PVT collectors are Gasokol in Austria and Solimpeks in Turkey. If you are aware of other covered PVT collector manufacturers, please contact the author: epp@solrico.com

Abora Solar purchases the thermal absorbers in Europe. The production line in Zaragoza is divided into four stages:

1. Laminating a photovoltaic module using purchased and stringed photovoltaic cells

2. Gluing the purchased heat absorber to the laminate

3. Casing the sandwich with insulation in the back and a front glass cover

4. Checking the power and quality in a flash-test

View into Abora Solar’s production hall in Zaragoza. Photo: Abora Solar

PVT factory of Dualsun at Jujurieux in France Photo: Dualsun

Dualsun: Switching to in-house made direct-flow aluminium absorbers

Dualsun from Marseille in France is one of the established manufacturers of uncovered PVT collectors, founded in 2010. “Our factory can easily be upgraded to follow market demand and now has a capacity of 30,000 PVT elements, corresponding to 15 MWel,” said Laetitia Brottier, Co-founder and Innovation Director at Dualsun. The company has just launched the fourth generation of its PVT elements called Spring4. Instead of the polymer absorber that was used in Spring3, Dualsun now relies on direct-flow aluminium absorbers that they produce in-house. The metal absorber is mechanically fixed to the PV element with an aluminium bar and springs.

“With an aluminium absorber we do not need a heat exchanger between the heat pump and the solar panel because the PVT element is resistant to the pressure of the heat pump’s primary circuit. And we can add fins, which improve efficiency at low temperatures in the useful range for the heat pump” explained Brottier. Dualsun used to laminate PV modules. Now the company has switched to specified OEM PV panels.

Structure of covered (left) and uncovered PVT collectors. Source: ISFH

Sunmaxx PVT: Rapidly growing demand – also for utility-scale systems

Sunmaxx PVT from Saxony, eastern Germany, is a startup founded in 2021. Like Dualsun, the company offers uncovered PVT collectors, which are usually operated in combination with heat pumps. The foundation of the company was supported by Mahle Group, an automotive supplier from southern Germany with 72,000 employees. PV cells are purchased and PV modules are laminated in-house. The company does not want to reveal whether the direct-flow aluminium absorber is produced in-house and how it is fixed to the PV panel.

The production plant has been built on an existing 4,000 m2 site and should have a production capacity of 120,000 panels per year, adding up to 50 MWel, according to a press release published in September 2023. “The demand for our modules – including for the construction of utility-scale systems – is growing rapidly and we want to scale the expansion of our production as quickly as possible. We started operation of our first line in December 2023, but the location will allow us to implement further expansion options to several hundred MW per year in a timely manner,” said Dr Wilhelm Stein, CEO of Sunmaxx PVT.

Factory site of Sunmaxx PVT in Ottendorf-Okrilla, Germany Photo: Sunmaxx PVT

Pa-ID: Experts in PV production and automation

The German company Pa-ID comes from the field of delivering machinery and automation services for PV module production. Since 2010 they have developed a PVT element. Series production started in 2012 in northern Bavaria. “With our current equipment we can build up to 40,000 collectors per year, totalling 17 MWel,” confirmed Pa-ID CEO Alban Heßberger. Pa-ID uses a direct-flow aluminium absorber for its 2Power panels, which is purchased from a specialized supplier.

Two of the four PVT manufacturers mentioned in this article have a Solar Keymark certificate already: Abora Solar and Dualsun (see Solar Keymark database). Sunmaxx PVT expects the publication of the Keymark certificate in the online database in the coming weeks.

Pa-ID has only a Solar Keymark certificate for the first generation of 2Power panels. “We have not certified our new 2Power panel because the certification process takes a very long time and the electrical performance classes sometimes increase faster than the certification complies”, explains Heßberger.

Websites of organizations mentioned in this news article:

Abora Solar: https://abora-solar.com/

Dualsun: https://dualsun.com/en/

Sunmaxx PVT: https://sunmaxx-pvt.com/

Pa-ID: https://www.pa-id.de/

Solar Keymark Database: https://solarkeymark.eu/database/