“Enclosed parabolic trough technology is only at the beginning of the cost reduction learning curve”

June 26, 2025

This quote comes from someone who knows all about the development of parabolic trough technology: Markus Balz. He spent over 20 years of his career at Schlaich Bergermann Partner (sbp), the international structural engineering and consulting firm, leading the development of technologies for solar power generation. In December 2022, he started as Chief Technology Officer at the then newly founded company Glasspoint. Together with three other former sbp colleagues, he works intensively at the Glasspoint Technology Center in Stuttgart on the further development and cost optimization of enclosed parabolic trough technology. We spoke with him about cost saving measures with a high impact and the so-called Holistic Digital Model that supports the innovation path. Photo: Glasspoint

At Schlaich Bergermann Partner you were responsible for the development of different types of parabolic trough collector which set the standards in several commercial CSP projects, for example in the USA, Spain, China and North Africa. What are the biggest differences compared to the enclosed trough technology that Glasspoint has developed?

Balz: Glasspoint started in 2010 with the first pilot systems in which the parabolic reflector was protected by a greenhouse. This was a breakthrough, as it considerably reduces the wind loads on the curved mirror, which can therefore be built much lighter. The glasshouse enables the mirror to have 1/6 of the material compared to an unprotected parabolic trough collector. You do lose about 5% of the irradiation through the glasshouse, but this is far outweighed by the reduced costs resulting from material savings and simplified corrosion protection.

The lightweight design has another important advantage. We can leave the receiver tube permanently fixed because we can rotate the lightweight mirror around the tube. With all the solidly built parabolic troughs in the market, the receiver tube is fixed to the mirror and rotates around the common centre of gravity of the construction.

What advantages are there if the receiver does not move?

Balz: Standard parabolic trough systems use moving receivers, which require a lot of swivel joints or flexible hoses. These components are not only expensive and maintenance-intensive, but they also limit the system’s working pressure and restrict the choice of heat transfer fluid ─ typically to synthetic oils ─ and therefore temperatures below 395 °C.

In contrast, a fixed receiver design allows for a much broader range of heat transfer fluids, including high-temperature liquid salts. This is possible because the design eliminates the need for self-lubricating swivel joints and enables straightforward gravity drainage across all components. It’s worth noting that the original Glasspoint system was designed for direct steam generation, with fixed tubes capable of withstanding pressures up to 100 bar ─ nothing one wants to try on a moving joint! Over the course of my engineering career, I’ve often heard the message from experienced mentors: ‘The best bearing is no bearing,’ which in this context translates perfectly to ‘The best swivel joint is no swivel joint.’

You used this technology on a large scale in the Miraah project in Oman. A total of 330 MW is installed in the dessert there for enhanced oil recovery. What were the experiences gained from building and operating the plant?

Balz: The system seems tohave been operating since 2017 and while we maintain regular contact with the client to offer support, they’ve been running the system happily themselves. Although operating solar direct steam systems for enhanced oil recovery presents certain control and operational challenges, it quickly became part of their daily routine.

The key lessons from this plant were less about the solar technology itself and more about the limitations of the glasshouse enclosure. Its small glass panes require a dense structural system and restrict further improvements in shading reduction. And the brittle nature of glass led to increased maintenance after sandstorms and higher air leakage, compromising the controlled interior environment. In addition, glass is relatively heavy but does not contribute to the stability of the building, in contrast to a tensioned foil.

As a result, in 2017, Glasspoint transitioned to a custom-designed fluoropolymer foil enclosure. This shift significantly enhanced structural stability, light transmission, airtightness, interior temperature control, and even halved embodied carbon ─ representing a major leap in both cost and performance. I can tell you that this switch was a true engineering achievement, resulting in numerous patents. And yes, the robotic cleaning system that runs along the roof continues to operate seamlessly with the new enclosure.

Demonstration plant of the second-generation enclosed parabolic trough design in Oman Photo: Glasspoint

Operation with liquid salt as a heat-transfer fluid is one of 20 cost reduction measures that you are currently investigating. What methodology do you use to assess and quantify the cost saving potential of particular measures?

Balz: We developed the Holistic Digital Model to optimize the performance and cost of complex concentrating solar thermal systems including large-scale thermal storage. This model integrates meteorological data and solar resource profiles to align system design with specific customer demand.

Out of an initial pool of 20 cost-saving measures, two emerged as particularly impactful in reducing the Levelized Cost of Heat (LCoH). The first was a shift in system configuration ─ from a hybrid setup with direct steam and liquid salt storage to a liquid-salt-only solution ─ which alone resulted in a remarkable 10 % reduction in LCoH because of the simplified plant design. The second was achieving customer acceptance of liquid salts as the heat transfer fluid instead of steam, which contributed an additional 8 % cost reduction. One promising innovation is closely linked here and this is the use of low-melting-point liquid salts. These salts melt at just 140 °C, compared to 290 °C for conventional salts, allowing the solar circuit to operate at lower temperatures during non-irradiation hours, thereby reducing heat losses. Notably, Glasspoint had already validated this approach in 2018.

What other measures with great potential are still on your list of cost-cutting measures?

Balz: We’re seeing a significant impact from the shift toward semi-robotic and fully automated production and installation processes. While the current Glasspoint system is already optimized for high performance and low cost, further improvements will need to be more heavily directed at labour costs. The system’s inherent simplicity makes it well-suited to robotic and semi-robotic installation, as well as on-site manufacturing of components. These advancements have the potential to significantly reduce construction time and further drive down overall costs.

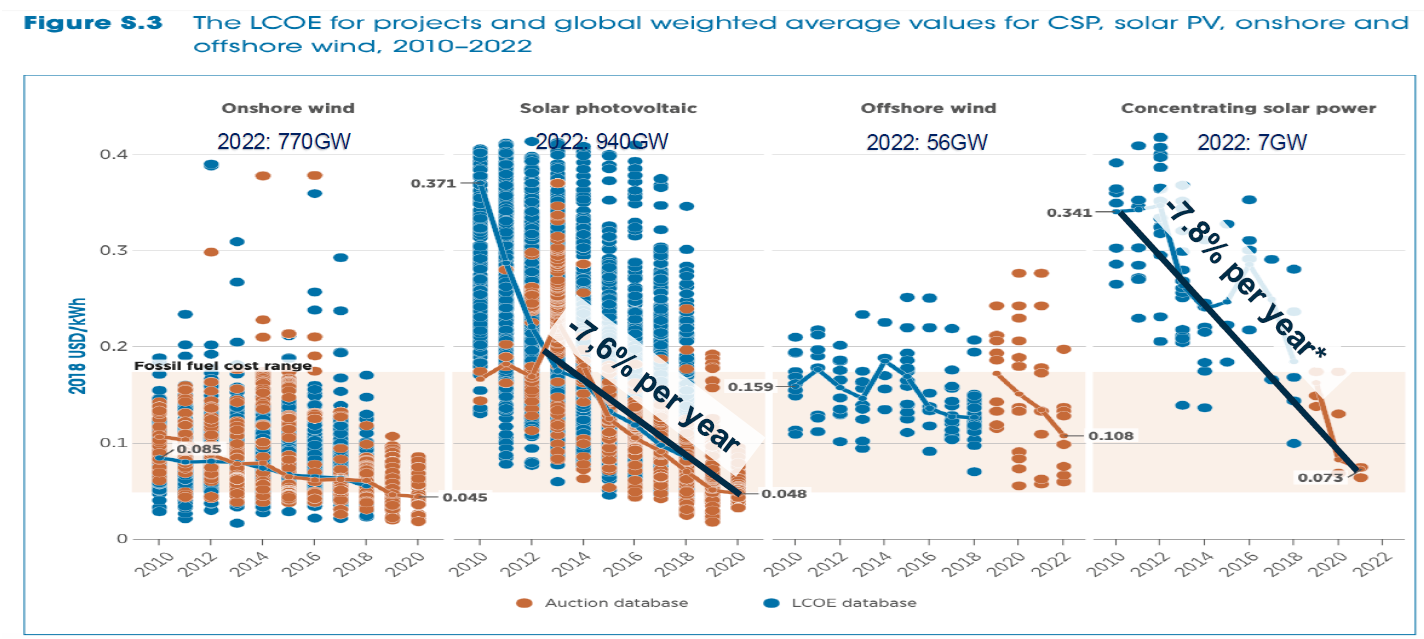

Figure 1: Chart from the Report Renewable Power Generation Cost in 2023 published by the International Renewable Energy Agency (IRENA)

“Glasspoint demonstrates LCoH reductions of up to 13 % per year across actual projects”

You like to quote the cost projections of the Renewable Power Generation Cost Report from IRENA to highlight that direct solar heat costs are declining faster than those of PV. How do you interpret figure 1?

Balz: I believe the answer is multifaceted. First, technologies tend to decline in cost through repeated application. Solar PV, for example, sees an average cost reduction of around 7 % per year – driven by its astonishing deployment rate of approximately 1 GW per day. In the chart above, PV is compared with CSP, which has seen less than 10 GW of capacity added over the past 12 years. Yet remarkably, CSP has achieved a similar levelized cost of electricity (LCoE) reduction – over 7 % annually – despite being deployed at less than 1% of PV’s scale. This highlights just how impressive CSP’s cost trajectory truly is.

Second, the chart focuses on electricity generation and LCoE, but the most significant cost reductions have actually occurred in the solar field technologies, which account for roughly 50 % of total CSP system costs. In contrast, the conventional power blocks – mature technologies refined over decades – have shown minimal cost improvement. This means that solar field technologies are advancing at a much faster pace.

Now, if we shift the focus to direct solar heat for industrial process applications – where no expensive turbines or power blocks are required – the cost declines become even more pronounced. In such cases, LCoH reductions can exceed 10 % annually. In fact, Glasspoint’s own history demonstrates real-world LCoH reductions of up to 13 % per year across actual projects.

What I’m really trying to emphasize is that enclosed trough technology is still in its early stages – it’s just beginning its cost-reduction learning curve. And yet it is already delivering impressive LCoH reductions without the need for massive R&D budgets – just a team of capable engineers and a few dedicated scientists.

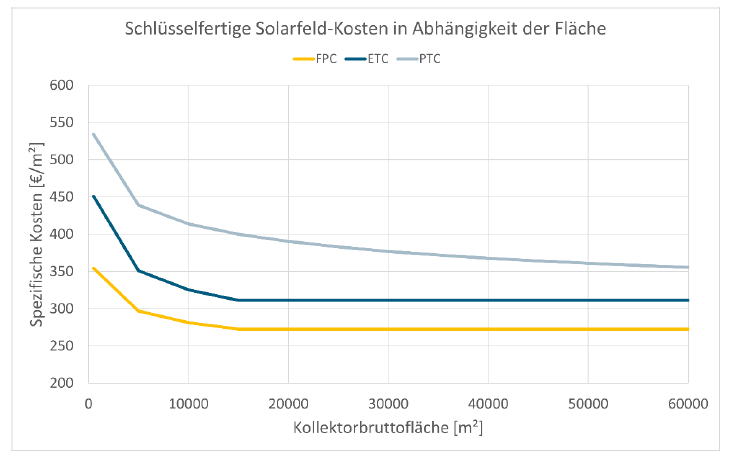

Figure 2: Turnkey solar field costs depending on the collector field size for three different collector types: FPC = flat plate collectors, ETC = evacuated tube collectors, PTC = parabolic trough collectors. Chart from the SHIP cost assessment study by Fraunhofer ISE, Germany

At the end of May 2025 the German Fraunhofer ISE published a cost assessment study about solar process heat in Germany. A key input parameter is the cost of the parabolic trough field – see figure 2. For a 60,000 m2 field, the reported cost is 350 EUR/m2 gross area. How does this compare to the results from your Holistic Digital Model?

Balz: I was very pleased to receive this report and its positive findings. We consider 60,000 m2 to be a pilot scale, where costs are heavily influenced by numerous one-time expenses – such as engineering, permits and implementation – that are disproportionately high compared to the cost of the solar field itself at this scale. As a result, direct comparisons are challenging. For the large-scale plants we develop, significantly lower costs are the norm.

Websites of organizations mentioned in this news article:

Glasspoint: https://www.glasspoint.com/

Schlaich Bergermann Partner: https://www.sbp.de/en/

Fraunhofer ISE: https://www.ise.fraunhofer.de/en.html

IRENA: https://www.irena.org/

Renewable Power Generation Costs in 2023: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2024/Sep/IRENA_Renewable_power_generation_costs_in_2023.pdf

SHIP Cost Assessment Study for Germany: https://solarthermalworld.org/news/germany-solar-process-heat-50-to-80-cheaper-than-gas-based-alternatives/