Australia’s strong role in the IEA SHC global solar heat collaboration

May 11, 2025

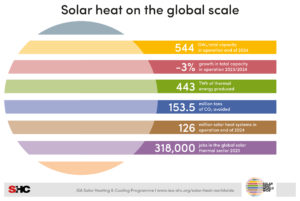

Australia remains a highly active participant in the IEA Solar Heating and Cooling Programme. Over the past three years, Professor Robert Taylor from the University of New South Wales has co-chaired Task 69, focused on Solar Hot Water for 2030. Continuing Australia’s active involvement, Doug Smith, CEO of Coolsheet PVT in Sydney, is now taking a leading role in the newly launched IEA SHC Task 73 on PVT Heating Systems. Globally, Australia ranks among the top ten markets for solar heat, with residential solar water heaters dominating installations. However, solar process heat is gaining increasing attention. Last year, the Australian Renewable Energy Agency (ARENA) committed AUD 17 million to a concentrating solar thermal plant for pet food manufacturer Mars Petcare in Victoria. Meanwhile, the Commonwealth Scientific and Industrial Research Organization (CSIRO) has been actively analyzing the economics of solar process heat solutions. The photo shows the 36 MW solar power plant at Sundrop Farms, a major tomato producer in South Australia. Photo: Aalborg CSP

“Australia’s involvement in the IEA SHC is a two-way exchange. Our researchers and industry representatives benefit from collaborating with colleagues around the world, while also contributing unique expertise, given Australia’s status as a well-established and significant solar heat market”, said Ken Guthrie, Australia’s representative on the IEA SHC Executive Committee. He is the Managing Director of Sustainable Energy Transformation based in Victoria and a Board Member of the Australian PV Institute, which is the Australian organization on the IEA SHC.

Growing competition from PV and heat pumps

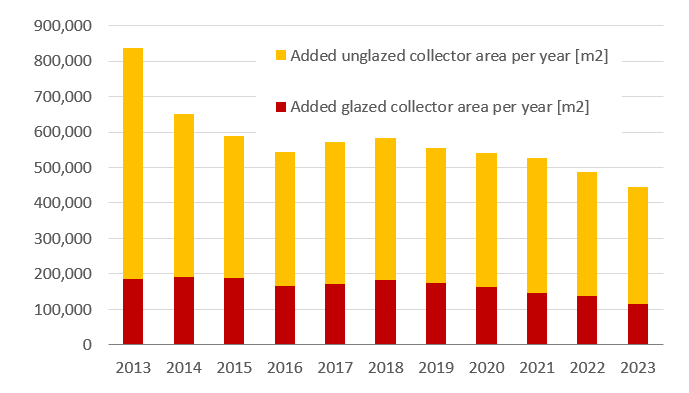

Figure 1 below illustrates the development of the Australian solar thermal market between 2013 and 2023. Throughout this period, the market was dominated by unglazed collectors used for pool heating, with annual installations fluctuating between 260 MWth and 280 MWth since 2013. The glazed collectors segment, however, is under increasing pressure from two alternatives according to Guthrie: photovoltaic systems, which are highly popular and occupy significant roof space, and air-source heat pumps, whose sales are rapidly expanding. Both PV systems and heat pumps such as solar water heaters are supported by the Small-Scale Renewable Energy Scheme. The scheme provides the same certificates to any renewable energy system at a capped price of AUD 40 (EUR ~23) for each megawatt hour of electricity deemed renewable that is generated or of grid energy that is displaced.

Figure 1: Australia’s solar heat market between 2013 and 2023 Source: Solar Heat Worldwide

This national subsidy programme is supported by requiring electricity utilities to purchase the certificates (STCs) to meet Australia’s renewable targets. The number of STCs awarded depends on the expected lifetime energy yield of the system. The definition of ‘small-scale’ varies by technology: for PV systems, it includes installations up to 100 kW; for solar water heaters, systems are limited to a maximum of 700 litres only; and for air-source heat pumps, the limit is 425 litres.

Guthrie also highlighted the nationwide House Energy Rating Scheme (NatHERS) as an innovative and well-implemented policy for reducing energy required by new houses and in some cases also renovations: “NatHERS rates thermal performance of homes on a 1 to 10 star scale, making it easy for consumers and building owners to understand energy efficiency outcomes.” 6-star is currently required for new-buildings, but this will soon to be increased to 7 star.

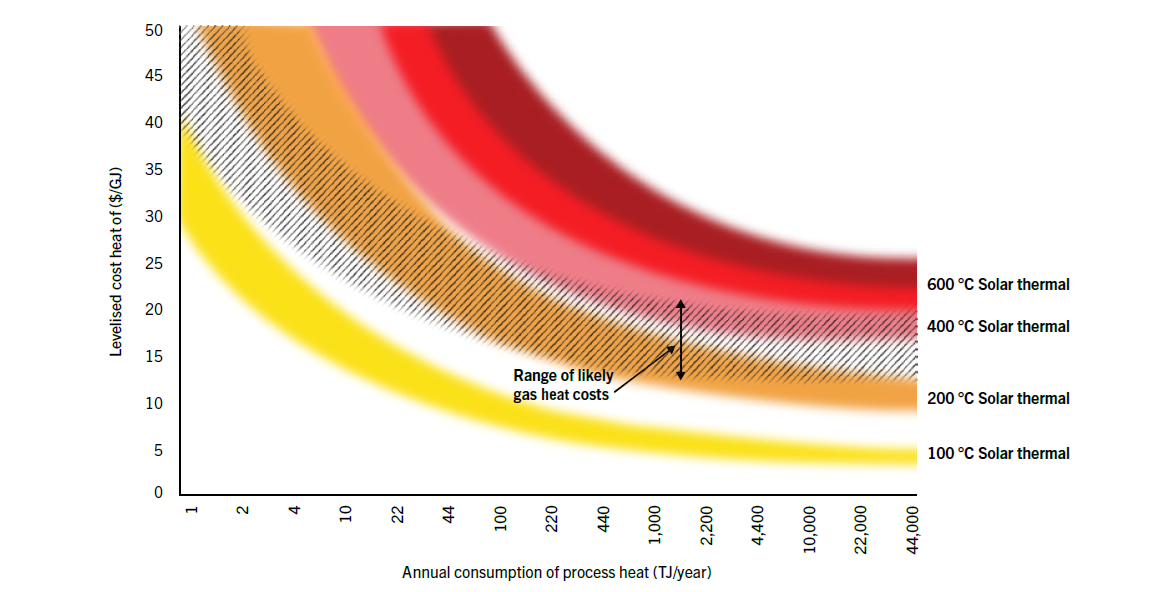

Figure 2: Cost of solar process heat depending on the system size and the temperature level. Source: ITP Thermal/CSIRO

Low level of experience with solar industrial heat solutions

Solar process heat is still in the early stages of market development in Australia. “There are relatively few commercial or industrial solar thermal systems in operation”, explained Guthrie. “However, large-scale photovoltaic (PV) installations are increasingly common on industrial and commercial sites. One key application is PV-powered cooling, particularly in data centres and office buildings.”

Demand for renewable process heat does exist. A recent report by ITP Thermal for CSIRO, The Australian Industrial Process Heat Market: Towards Zero Emissions, estimates that around 15,000 industrial sites in Australia currently use process heat. The industrial sector accounts for 47 % of the country’s total end-use energy, with process heat comprising 42 % of that figure. Despite this significant demand, “the level of industrial experience with renewable heat remains low”, the report notes, citing key barriers such as a low appetite for risk and a preference for short payback periods.

A further challenge for the solar process heat market is the “historically low gas prices”, as Guthrie notes. However, the ITP Thermal / CSIRO report concluded that low-temperature process heat below 100 °C is cost-effective against even the cheapest fossil fuel heat from coal and gas (see Figure 2). Solar heat systems for higher temperature also result in higher heat costs, which can be compensated by economies of scale in larger fields. The authors of the report analyse figure 2 in the following way: At 200 °C process heat for example, the solar collector systems must provide more than 50 terrajoules (TJ) annually (corresponding to 13.9 GWh) to be cost-competitive against gas and at 400 °C the annual heat provided by solar must even be greater than 400 TJ/year (111 GWh/year).

ARENA has also discovered the need for funding for clean process heat. In March 2025, the agency opened the second round of applications within the Industrial Transformation Stream (ITS) programme which made AUD 70 million (EUR ~40 million)available for funding of feasibility and engineering studies and for demonstration and deployment projects. In addition to solar thermal, heat pumps, storage tanks and electric boilers are also subsidised.

PVT elements made in Australia (from left); Amr Omar and Prof Robert A. Taylor from the University of New South Wales, and Tom Hoole and Doug Smith from Coolsheet Photo: TRaCE – Trailblazer Recycling & Clean Energy program

Largest commercial-scale PVT installation for a public pool

Doug Smith sees a gas shortage arising in the country as ageing gas fields go offline in 2028. This is already driving prices to uneconomic levels for water heating and accelerating the move to decarbonized process heat for commercial and industrial users. The issue, he notes, stems from the lack of a gas reservation policy in Eastern Australia and major investments into LNG exports for the past 15 years, which has resulted in 75 % of Australia’s gas being sold overseas at higher profit margins than within the country.

Coolsheet offers an innovative solution to help customers get away from gas: a heat exchanger panel that attaches to the back of solar PV modules to capture excess heat from the solar cells. The company will initially focus on commercial and industrial clients, having begun development of its photovoltaic-thermal (PVT) technology in 2018, with patents now granted in Australia, Europe and the USA.

Coolsheet’s first commercial-scale, pilot installation is scheduled to begin operation in the second half of 2025 at the newly renovated Olympic pool in the centre of Sydney. In combination with ocean water heat exchangers, 110 kW of PVT panels will serve as an additional heat source for the heat pumps that will maintain comfortable swimming temperatures year-round across all five pools in the complex.

Smith is also actively involved in the newly launched IEA SHC Task 73 on PVT Heating Systems, contributing to efforts in awareness-building and policy advocacy. “It’s great to collaborate with global leaders in PVT technology and share knowledge to support one another,” he says. He is particularly focused on advocating for a level playing field when it comes to subsidies. Currently, PV combined with air-source heat pumps qualifies for support under Australia’s Small-Scale Renewable Energy Scheme, while PVT systems are not yet recognized. Furthermore, water-source heat pumps receive significantly less financial support than their air-source counterparts. Smith believes policy changes in this area could make a significant impact on the young but promising PVT market in Australia.

Websites of organizations mentioned in this news article:

Task 73 PVT Heating Systems: https://task73.iea-shc.org/

Task 69: Solar Hot Water for 2030: https://task69.iea-shc.org/

University of New South Wales: https://www.unsw.edu.au/

Small-Scale Renewable Energy Systems scheme: https://cer.gov.au/schemes/renewable-energy-target/small-scale-renewable-energy-scheme/small-scale-renewable-energy-systems

Report The Australian Industrial Process Heat Market – Towards Zero Emissions: https://itpthermal.com/wp-content/uploads/2025/04/itpproccess-heat-report_final08042025.pdf

Industrial Transformation Stream Support Scheme: https://arena.gov.au/funding/powering-the-regions-industrial-transformation-stream/

Coolsheet : https://www.coolsheet.com/

Sustainable Energy Transformation: https://setransformation.com.au/

Australian PV Institute: http://www.apvi.org.au

Trace/Trailblazer Recycling & Clean Energy: https://trace.org.au/converting-waste-heat-from-solar-panels-into-zero-emissions-water-heating