2,600 m2 Inspire solar air façade heats factory in Pennsylvania

October 20, 2022

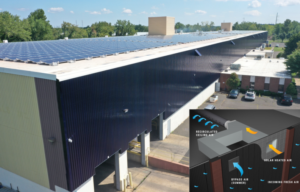

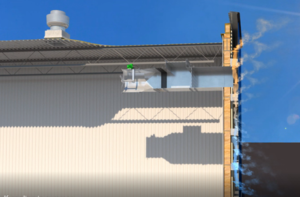

The US American company ATAS International has constructed its first large commercial solar air heating system with its new Inspire HP air collectors. The south façade of the production hall at Brightsmith Coil Coaters in Morrisville, Pennsylvania is now covered with 2,600 m2 of Inspire collectors. The solar façade heats the factory building during the heating season. In summer the solar heated air is allowed to escape upwards and the wall cools itself via natural convection. The novelty of the Inspire HP collector is the selective coating, which is resistant to outdoor conditions. HP stands for high performance.

Photo: ATAS International

“We have offered solar air heating solutions over the last 20 years to commercial companies, but mostly to institutional customers with a high need for fresh air in their buildings such as malls, hotels, schools, sports facilities, transit authorities or factories that handle paint or chemicals,” explained Dick Bus, President of ATAS International. The core business of the company is metal wall and roof systems. Solar air heating currently contributes only 1 % to the turnover, but Bus reports increasing interest in ATAS’s solar products.

The ATAS air collectors consist of 0.7 mm thick aluminium plates, which are perforated and profiled. ATAS´s production line starts with the aluminium sheet on a coil and ends with a finished, cut to length and stacked metal profile. It is a completely automated manufacturing unit. Volumes could be scaled up easily depending on demand.

Selected coating increases yield by 25 to 35 %

ATAS has worked with the German solar coating specialist Almeco Group for several years to develop a selective coating for its air collectors that withstands outdoor climate conditions. “We tested the first prototype of Inspire HP back in 2019 on our own test bench,” said Christian Vachon, the Director of Solar Technology at ATAS. The new Inspire HP collector has an SRCC and a Solar Keymark label. According to the manufacturer, the improved collector design shows a 25 to 35 % increase in yield over the former generation of Inspire solar air collectors with black paint. This has been proven through side-by-side testing and field monitoring of at least 20 systems, confirmed Vachon. A direct yield comparison based on certification results is not possible. The black-painted Inspire collectors were tested back in 2014 in Canada and the results are not comparable to the Solar Keymark certificate of Inspire HP from Switzerland dating from 2020.

Fresh air flows through the small holes in the metal profiles into the channels behind the façade and enters the building via air channels. Photo/Graphic: ATAS International

Largest single-wall solar air heating system

“The Brightsmith installation is the largest single-wall system we have ever realised at ATAS”, confirmed Vachon. ATAS has sold more than 200 solar air collector projects over the last 20 years, but mostly in the new-building market. The Brightsmith system is a retrofit project and therefore represents an exception for ATAS. The existing ventilation system, designed as far back as the 1960’s, was outdated. The retrofit process was a good chance to integrate the solar air heating system. There was also this façade, which is over 280 m long and points almost perfectly south.

The factory was previously heated with gas boilers. According to Vachon’s estimates, the solar air ventilation system together with new destratification units can save 45 to 50 % of the conventional energy that was used for heating before. This relatively high reduction percentage is only feasible for buildings which have not used air heat recovery systems, but let fresh air directly into the building.

During installation: A framework is installed on the façade first before the metal collector profiles can be hung on the wall

Photo: ATAS International

Combining solar air heating systems with destratification ventilators

According to Vachon, it was an engineering feat to integrate the solar air distribution system together with the destratification ventilators into the existing production hall. The loading crane goes almost to the ceiling, not leaving much room for the solar air distribution system.

The destratification ventilators are installed under the ceiling of the factory and have long rotor blades. When they turn, they push the warm air that tends to collect at the top back down to the floor. Vachon always recommends architects and engineers to combine the solar air heating system with destratification ventilators. The above-mentioned energy saving of around 50 % is half generated by the sun and half by the destratification units. If it is not sunny enough, the air heating system either pulls warmer air from the ceiling into the air channels or uses gas-heated fresh air.

| Site of the factory building | Morrisville, Pennsylvania, USA |

| Production process in factory building | Metal coil coating process |

| Area of air collector system | 2,600 m2 |

| Type of air collector | Unglazed, transpired solar air |

| Average air flow | From 120,000 to 435,000 m3/h |

| Number of air inlets along the wall | 15 total |

| Number of destratification fans | 5 |

| Capacity of destratification fans | 60,000 m3/h |

| Unitary air flow range | From 40 to 170 m3/h per m2 of collector |

| Maximum air temperature rise above ambient | Up to 50 °C (90 °F) |

Key figures for the solar air heating system at Brightsmith. Source: ATAS International

Coil painting processes like those performed at Brightsmith require high ventilation rates at four air changes per hour. This means an air flow of 435,000 m3 per hour. This is not a problem for the huge perforated metal façade that can handle up to 170 m3/h of air per m2 of collector area. “It is an advantage compared with glazed air heating solutions that we can supply very high flow rates with our unglazed transpired collectors,” said Vachon.

The self-cooling effect of the solar wall in summer when there is no heating needed in the factory. The solar air is not let into the building but flows out of the cladding through the holes at the top.

Photo: ATAS

Organisations mentioned in this news article:

Inspire HP: https://inspirewall.com/inspire-hp/

ATAS International: https://www.atas.com/

Almeco Group: https://www.almecogroup.com/en