Bridging the gap between PCM research and real-world storage

January 27, 2026

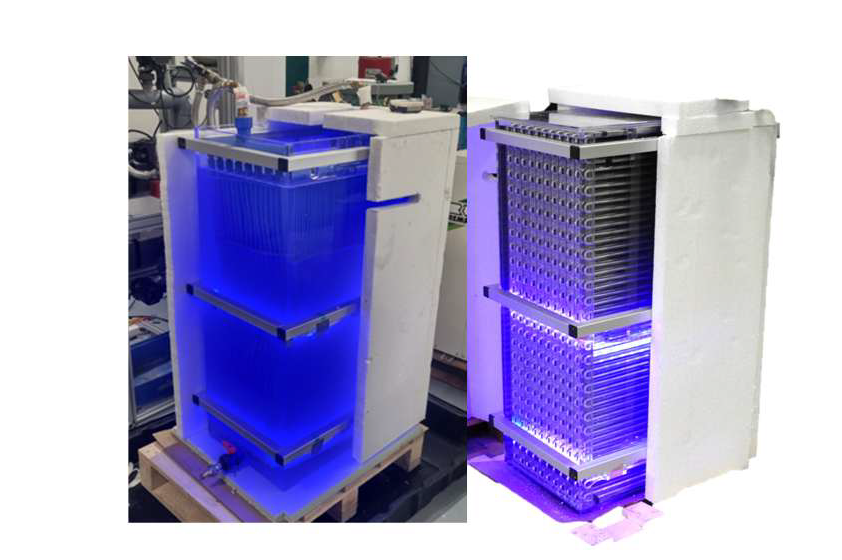

In recent years, research into compact thermal energy storage has focused primarily on the development of storage materials. This focus is now set to broaden. The IEA SHC Programme has launched a new research group dedicated to Components for Thermal Energy Storage. “We would like to bridge the gap between storage materials and practical implementation”, explained Wim van Helden from AEE INTEC in Austria, which manages the group under IEA SHC Task 75. It met for the first time in October 2025 in Stockholm. Three suppliers of thermal energy storage material and systems took part in the kickoff meeting: Iceheart from Sweden, Rubitherm from Germany and PLUSS from the Netherlands. We spoke with two of the companies about their motivation for joining the task and their technology portfolio. The photo shows PhaseTube, a storage unit that can be used for either cooling or heating, depending on the phase change material (PCM) employed.

Photo: Rubitherm

“It was a good initiative to take part in the kickoff meeting. It was a very well-organized workshop with interesting subjects”, summarized Jan Sjöberg, CTO at Iceheart. “Our aim is to stay well-informed about the progress of cold storage technologies using phase change materials, plus we would like to contribute with our experience in industrial implementation of cold storage technologies.”

“Our special knowhow is the way to extract the cooling powe”

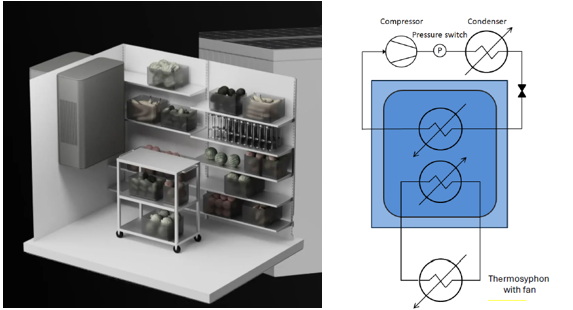

Iceheart is a startup company founded in 2022. After four years of development, the ice storage Iceheart COU26 has been tested and is almost market ready. “We have installed demonstrators in Spain, Sweden, Kenya and Italy. Presales have started and the market launch of Iceheart COU26 is planned for the third quarter this year”, explained Sjöberg. A typical application is cold rooms for food storage, typically around 4 °C.

The storage has a volume of 250 litres. A conventional cooling unit freezes the water to ice. For this purpose, a standard copper pipe heat exchanger with aluminium fins is inserted into the storage tank.

“Our special knowhow is the way to extract the cooling power from the ice in a controlled and efficient way adapted to the cooling needs of the cold room”, said Sjöberg. The company uses a thermosiphon circuit which includes fans that distribute the cold air into the room. The advantage is that the cooling energy extraction does not depend on the power of the compressor and can be up to 10 times higher than the compression power for short periods, according to Iceheart.

Optimal economic operation can be achieved by using grid power at low-cost times to run the chiller and then cool the room using the storage when electricity prices are high. If the grid is unstable, the Iceheart COU26 can operate for up to 7 days without being charged via the chiller, avoiding a lot of food waste.

Iceheart COU26 for cold food storage rooms on the left and its main principle using a thermosiphon circuit with fans on the right Graphics: Iceheart

“PCM storage units behave differently to water storage”

Dr Esther Kieseritzky, General Manager of the German company Rubitherm, is also very positive about her participation in the kickoff meeting of IEA SHC Task 74: “A lot of the topics covered in the task are also highly relevant for us in our daily work to improve PCM storages. Therefore, we think that the exchange between different stake holders and collecting/summarizing research from so many players will help us and others to improve PCM storage systems.”

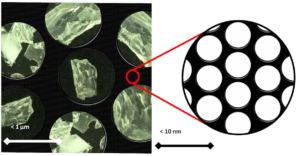

Rubitherm has worked on developing TES with PCMs intensively since 2015. One result of this long-term development is the PhaseCube storage system for air conditioning in homes. It was launched in 2020 and is offered Europewide. The storage unit contains 10 aluminium plates; each filled with 2 kg PCM. The distance between each plate is 5 mm, which means that the pressure loss is very low. Air flows past these plates, transferring heat away. The PhaseCube is charged at night; therefore the location needs a day/night temperature difference that falls into a suitable range. The type of PCM can be chosen depending on typical summer night temperatures, for example SP21EK with a melting point of 21°C for German homes or SP25 with a melting point at 25°C for Spanish homes.

PhaseCube is an air conditioning storage that consists of PCM-filled aluminium plates with a special corrugated surface. Air flows between the aluminium plates and is cooled down. Photo: Rubitherm

During her presentation at the kickoff meeting Kieseritzky made clear that PCM storage units behave differently to water storage units. “Nobody seems to ask what kind of performance and capacity a water storage unit has. This information is usually not included in the data sheets”, commented Kieseritzky. However, performance, capacity and volume flow have a strong influence on how a PCM storage tank is used.

For example: a high temperature difference between inlet and melting point results in more capacity but lower performance. Whereas a small temperature difference and small volume flow lead to a smaller capacity but higher performance. There are many possible combinations and Rubitherm has compiled them in an overview table (see below). If you choose for example the performance at a temperature difference between inlet and melting temperature of 5 K at a flow rate of 40 litres/min/m3, the chart now answers the question of how long it takes to charge the storage tank. In the example the storage tank is 74 % charged in four hours and 81 % in six hours. “If this is too long, then I have to use, for example, a greater temperature difference. With 6 K and the same volume flow the storage is already filled up to 80 % in four hours”, explained Kieseritzky.

Charging times for a 200 litre PCM storage filled with SP31 under different operating conditions. Table: Rubitherm

The contributions from companies like Iceheart and Rubitherm underline the fact that compact storage technologies are already technically mature but still require better integration, clearer performance metrics and shared knowledge across stakeholders. By bringing researchers and manufacturers together, the new Task 75 aims to facilitate the step from material and component research to reliable, market-ready thermal storage solutions.

Websites of organizations mentioned in this news article:

IEA SHC Task 75 Components for Thermal Energy Storage: https://task75.iea-shc.org/

AEE INTEC: https://www.aee-intec.at/

Iceheart: https://www.iceheart.com/

PLUSS: https://plussat.eu/

Rubitherm: https://www.rubitherm.eu/en/