Growing demand for industrial heat pumps drives innovation in heat exchangers

December 15, 2025

Demand for industrial heat pumps is growing. Customers want heat pumps with large capacities and, if possible, with natural refrigerants. This calls for advanced heat exchangers for condensers and evaporators. The German agency solrico conducted a survey among heat exchanger manufacturers to find out what requirements are placed on heat exchangers (HEXs), what advantages and disadvantages plate versus shell-and-tube HEXs have and what market trends can be observed. Five major manufacturers in Europe took part in the survey: Alfa Laval and SWEP from Sweden as well as Hexonic, Kelvion and Wieland from Germany. The survey was supported by the International Copper Association Europe. Please note that the survey considered only water/water industrial heat pumps that provide heat between 80 and 130 °C and have a thermal capacity of between 100 kW and 2 MW.

Chart: solrico

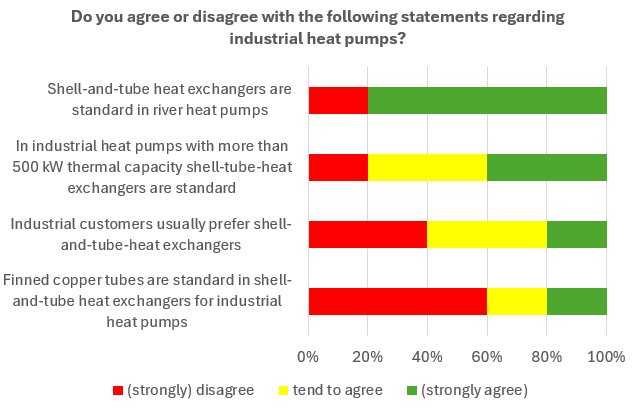

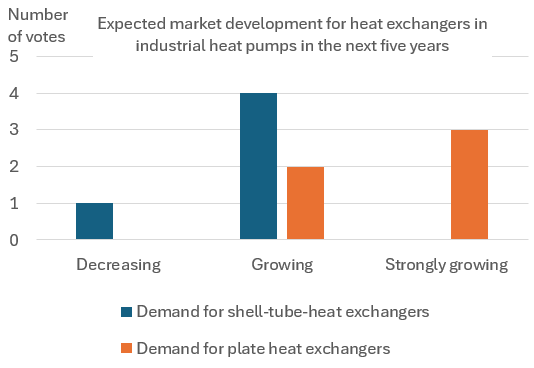

“The market for industrial heat pumps will have a double-digit growth curve in the coming decade in which both plate and shell-and-tube HEXs have their place”, is how one surveyed company commented on the market development. The graph above gives the impression that more plate HEXs will be used in the future than at present. This result must be viewed in conjunction with the results shown in the chart below. This chart shows how certain trends are assessed in relation to shell-and-tube HEXs.

Four of the participating five companies agree with the statement that shell-and-tube heat exchangers are standard in river heat pumps. The result here is quite clear. This has to do with contamination and corrosion issues from river water at the heat source, because shell-and-tube HEXs can be cleaned, unlike brazed plate HEXs.

The question of whether industrial customers generally prefer shell-and-tube heat exchangers was assessed differently as well. Only one company fully agrees with this, two participants disagree.

The third statement was “For industrial heat pumps with more than 500 kW thermal capacity shell-and-tube HEXs are standard”. In general, shell-and-tube HEXs are used in heat pumps with larger capacities, but 500 kW is probably too low in terms of thermal output as two companies only partially agree with the statement and one company disagrees.

SWEP, for example, stated that its range of plate HEXs goes up to 700 kW and also have alternatives for refrigerant CO2 with working pressures up to 140 bar. Current developments at SWEP include plate HEXs with 1 MW. Wieland currently offers plate HEXs up to 700 kW, depending on the fluid/refrigerant used and the operating conditions. Kelvion manufactures a high-pressure laser-welded cassette plate heat exchanger series in the 0.5 to 4 MW range. Alfa Laval stated that their semi-welded plate heat exchangers can also handle big capacities up to 15 MW with up to 160 °C. Hexonic relies on a combination of plate and shell-and-tube HEXs which are currently provided as units with up to 1.5 MW that can handle 100 bar and up to 200 °C. In this JAG-Shield technology, laser-welding is used to join plates in pairs, which are connected along the entire outer circuit. JAG-Shield HEX can reach 3 MW.

Large capacities and natural refrigerants: key trends driving innovation in HEXs

The survey showed that a lot of R&D is currently being invested in the development of HEXs which can achieve higher capacities and withstand higher working pressures. Alfa Laval, for example, has explored brazed-plate HEXs for CO2 as a refrigerant with thermal capacities up to 800 kW and pressures up to 130 bar. Hexonic confirmed that HEXs for heat pumps in the MW-scale with natural refrigerants are currently the focus of research. The L-Ultra series of brazed heat exchangers with up to 600 kW, for example, operates with CO2 up to 150 °C and 140 bar. SWEP stated that the company has updated its plate HEX portfolio with new models to meet requirements for medium-pressure refrigerants such as 1234ze, isobutane, pentane, 1233zd, improve evaporator duty and increase capacity These units can be operated up to 32 bar.

In general, industrial heat pumps are still a relatively new market segment that is currently undergoing dynamic development, which is why many different opinions and views of the market were received. “Over time, this will become more settled,” emphasized one of the survey participants.

Pros and cons of plate and shell-and-tube HEXs

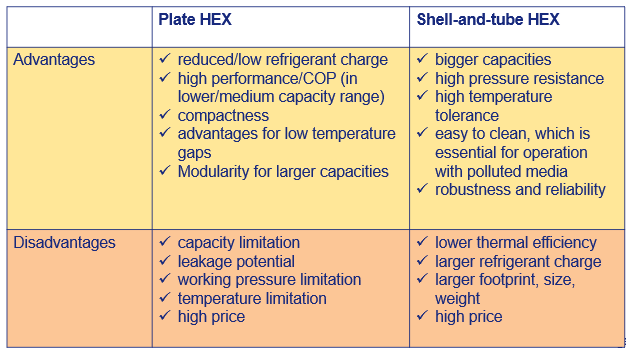

In the survey, HEX manufacturers were also asked to list the advantages and disadvantages of plate and shell-and-tube HEXs. The results are summarized in the following table. The responses here were rather consistent across the various companies. Shell-and-tube HEXs are clearly used in large heat pumps because of their high pressure resistance, high temperature tolerance, and – as described above – when the source water is contaminated. “Shell-and-tube HEXs are gaining importance in applications requiring high pressure and a low pressure drop”, according to a statement from one participant.

Plate HEXs have the advantage of being more compact, having higher heat transfer capacity due to their larger surface area and requiring a smaller refrigerant charge. This makes plate heat exchangers suitable for applications where there is a small temperature difference between the heat source and heat sink. “Plate HEXs have the advantage of compactness and good performance in the low/medium capacity range up to 700 kW”, said one of the participating companies.

Summarized answers to the question What are the advantages of the two different HEX types?

Source: solrico

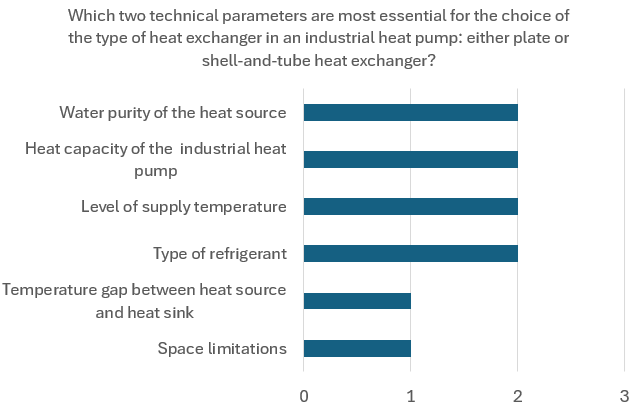

The survey also asked “Which two technical parameters are most important for the choice of the type of heat exchanger in an industrial heat pump?” The answers to this multiple-choice question were very diverse (see figure below) with all six parameters being ticked fairly evenly. This shows how much the choice of HEX depends on various conditions.

Websites of organizations mentioned in this news article:

International Copper Association Europe: https://copperindustryeu2030.eu/

Alfa Laval: https://www.alfalaval.co.uk/

Hexonic: https://hexonic.com/en/

Kelvion: https://www.kelvion.com/

SWEP: https://www.swepgroup.com/

Wieland: https://www.wieland.com/en