“We absolutely recommend this investment to other manufacturers”

October 15, 2025

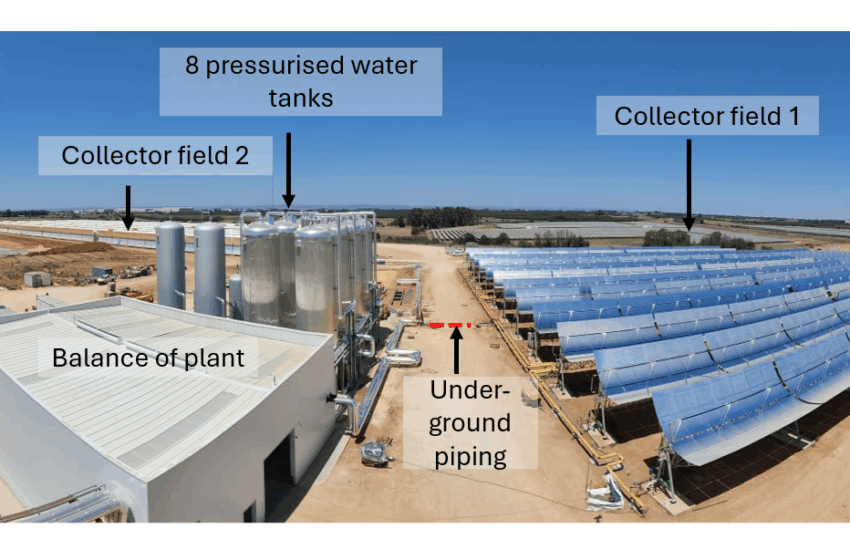

The solar process heat plant at Heineken in the Spanish town of Seville stands as a flagship project in several key respects. Remarkably, it was completed in just 13 months, from groundbreaking to commissioning. With a capacity of 30 MW, it is the largest solar process heat plant in Europe. Most notably, the customer – Heineken Brewery – has expressed satisfaction with its performance and operational efficiency. The photo shows the view of the solar process heat plant with the storage tanks and balance of plant on the left and one of two parabolic trough fields on the right. The solar plant is owned and operated by energy provider Engie España, under a 20-year heat supply agreement with Heineken.

Photo: Solarlite CSP Technology GmbH

“We absolutely recommend this investment to other manufacturers. It’s a scalable and forward-looking solution and a symbol for Heineken’s commitment to sustainability and innovation”, said Consuelo Carmona, Technical Manager of Sustainability Heineken España. She confirmed that the “progress in fine-tuning the system so far is encouraging, and we are confident in the long-term value of this solution.” Heineken also sees the use of water as a heat transfer fluid, instead of synthetic oil, as a great environmental advantage.

Other special features of the solar process heat plant:

- The parabolic troughs are identical in size and structure to those of large concentrating solar power plants for electricity production (12 m x 5.77 m).

- The storage volume consists of eight stratified, pressurised steel tanks with a total volume of 800m3.

- Some of the major collector components – receivers and mirrors – were shipped from China, but the entire solar field installation work was led by Azteq/Solarlite Spain and carried out by an Andalusian construction company

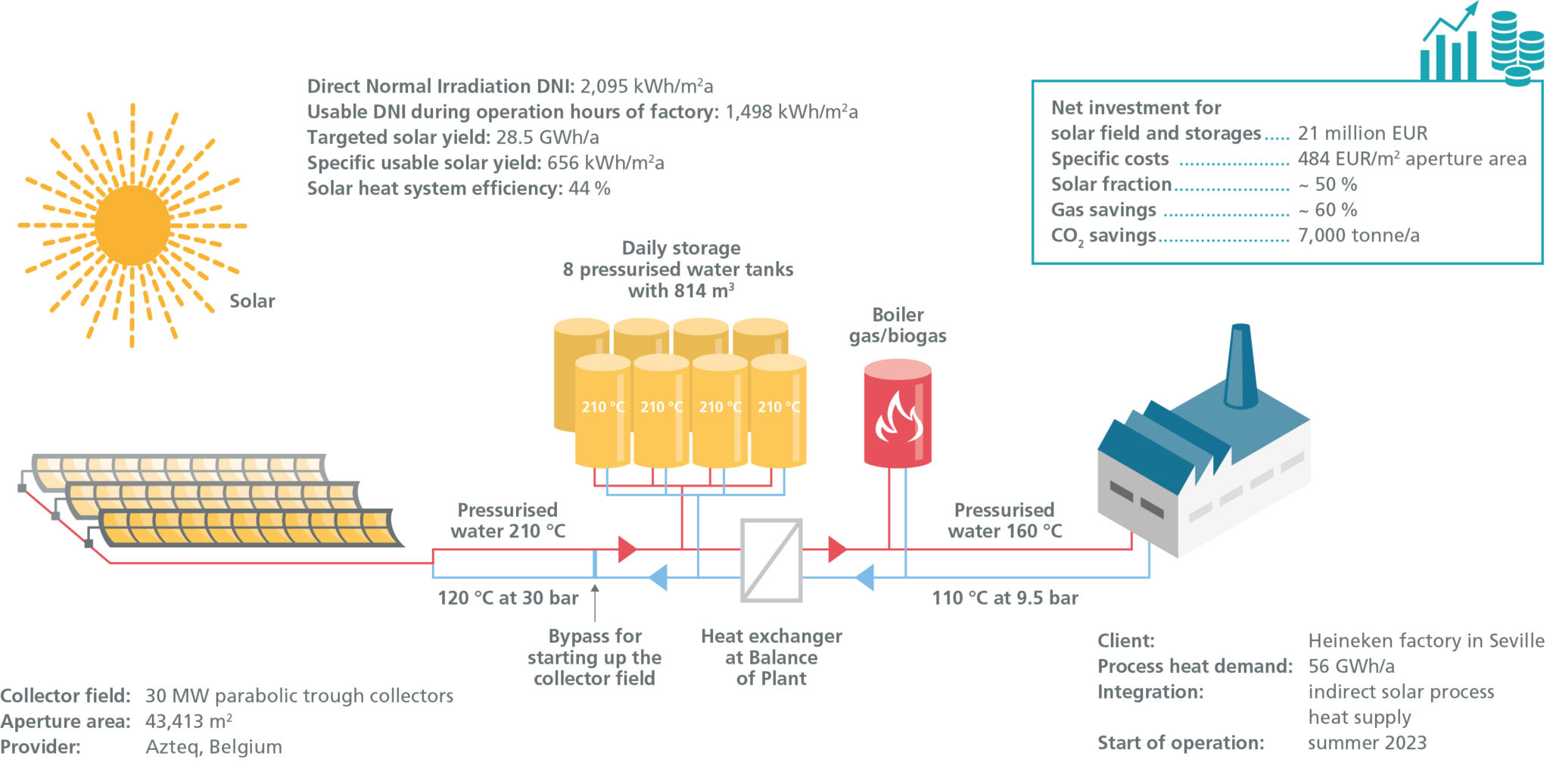

Schema of the solar process heat plant at Heineken in Sevilla, Spain Source: ProSolNetz

Plant specifications at a glance

The diagram below illustrates how the solar thermal system is seamlessly integrated into the factory’s infrastructure. A heat exchanger separates the solar collector field from the customer’s pressurized water system, ensuring that the solar input does not interfere with the existing heat supply network of the client. Additionally, a bypass in the solar circuit allows the heat transfer medium to circulate through the collector field until it reaches 210°C. Thanks to the HEX design, the solar field and the storage can supply the inlet to the heat exchanger within a flexible range of 170 to 210 °C, which is sufficient to ensure that the client’s required supply temperatures are consistently met.

The solar process heat plant is designed to deliver an annual usable solar yield of 28.5 GWh, covering approximately 50 % of the factory’s total heat demand of 56 GWh per year. The brewery works five days a week. Based on the site’s annual Direct Normal Irradiance of 2,095 kWh/m²a, this results in an overall system efficiency during the 261 working days of 44 % – accounting for all system losses.

With such a high solar fraction of 50 %, there may be excess heat during the sunny summer months. For this reason, the parabolic trough collectors at Heineken were arranged in an east–west direction. This orientation was chosen for two main reasons: firstly, it provides a marginally better annual heat supply at the client interface, as it balances heat production with the demand profile and reduces the risk of dumping solar energy during periods of low heat demand in the factory; and secondly, it allows for a more compact and optimised fit within the available land size and shape. Although the plant achieves its highest yields around solar noon and comparatively less during sunrise and sunset than a north–south facing field, the east–west configuration was ultimately the best match for the site-specific constraints and the brewery’s load profile.

Websites of companies mentioned in this news article:

Heineken: https://www.heinekenespana.es/age-gate/8717

Engie España: https://www.engie.es/

Azteq Energy: https://azteq.energy/

Solarlite: https://www.solarlite.de/