A guideline for industrial heat pumps adapted to district heating networks

October 4, 2024

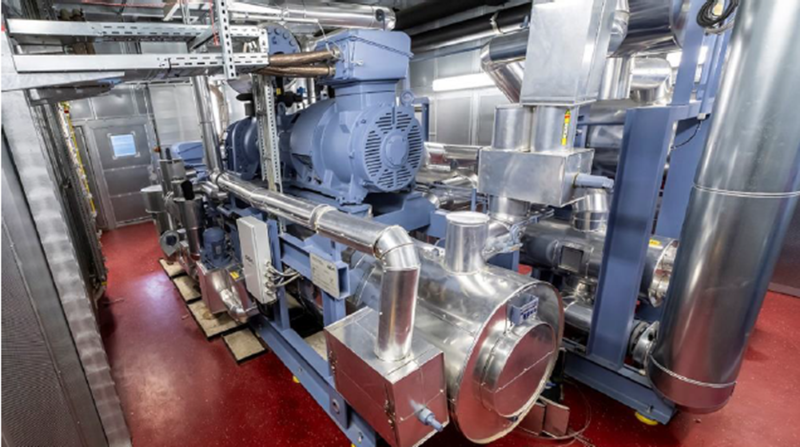

Solar thermal systems and heat pumps are important key components for the decarbonization of district heating networks and often complement each other well. Heat pumps can, for example, use heat from the solar-charged seasonal storage tank and thus empty it more efficiently. This boost effect of heat pumps was described here. In a series of articles, we will present various projects with industrial heat pumps that provide heat between 65 and 95°C for heating networks. This requires special high-performance compressors. In addition to these, the choice of refrigerant is also decisive for the efficiency, as is the available heat source. The photo shows a 2.4 MWth heat pump at Stadtwerke Lemgo, Germany, which was manufactured and installed by Global Engineering Alliance (GEA), Germany. Photo: GEA

According to our interview with Dr Cordin Arpagaus from the OST Eastern Switzerland University of Applied Sciences, the following four heat pump suppliers are among the established companies in this field: GEA, Ochsner, Johnson Controls International und Friotherm. Table 1 shows a selected district heating project for each of these manufacturers. A wide range of compressor technologies, refrigerants and heat sources are used in these projects.

| Client | Stadtwerke Lemgo, Germany | Hall AG, Austria | Stadtwerke Heidelberg, Germany | Blockheizkraftwerks, Träger- und Betreibergesellschaft mbH Berlin (BTB), Germany |

| Supplier of heat pump | Global Engineering Alliance (GEA), Germany | Ochsner Energietechnik, Austria | Johnson Controls International, Denmark | Friotherm, Switzerland |

| Type of heat pump | GEA RedAstrum | IWWS 900 R6a

IWWSV 980 ER6a |

Sabroe HeatPac | Unitop 28/22CY |

| Total thermal capacity of heat pump | Two units of 1.2 MW each | Four units of 300 kW to 1.1 MW modulating | Three units of 1.35 MW | Two units of 3.5 MW each |

| Year of commissioning | 2019 | 2021 | 2023 | 2023 |

| Type of compressor | Screw | Screw | Piston | Two-stage turbo |

| Type of refrigerant | R717 (ammonia) | R1234ze | F717 (ammonia) | R1234ze |

| Type and temperature of heat source | Sewage water at 7 to 22 °C | Exhaust gas from boilers | Air of at least 5 °C | River water of at least 8 °C |

| Temperature level of delivered heat | 63 to 82 °C | 65 °C | Up to 90 °C | Up to 90 °C |

Table 1: Overview of the most important key data for the four selected heat pump projects for district heating networks, which will be also presented in individual articles.

Source: manufacturers’ information

As an introduction to the topic of industrial heat pumps on solarthermalworld.org, we are starting with this overview article, which presents the most important features of this technology. We will use the “Praxisleitfaden Großwärmepumpen” (Practical guide to large heat pumps), which was published by the German district heating association AGFW in 2023. Source: AGFW

Types of compressor

Three main compressor technologies are currently used in industrial heat pumps for district heating (see also table 1): turbo, screw and piston compressors. The compressor technology used influences temperature limits and efficiency as well as the overall investment volume and the maintenance costs and intervals. If compression is carried out using several compressors, this is referred to as a multi-stage system.

“At present, systems with piston compressors often require a lower investment than screw compressors”, conclude the authors of the guide. “But maintenance costs are higher due to shorter maintenance intervals and more complex maintenance work. The authors of the guide therefore recommend taking the total life cycle costs of a system into account when making an economic assessment.”

Types of refrigerant

Refrigerants can be divided into two categories: natural refrigerants and synthetic refrigerants (see table 2). Natural refrigerants are substances that also occur in nature. Synthetic refrigerants are artificially produced fluorinated gases (F-gases).

The climate impact of refrigerants is determined on the basis of the ozone depletion potential (ODP) and the global warming potential (GWP). The majority of refrigerants currently under consideration have an ODP value of zero or at least close to zero, so that this value is hardly relevant for a decision in practice. The GWP value, on the other hand, is much more relevant due to regulatory restrictions.

| Type of refrigerant | Climate impact | |||

| Designation | Substance | ODP | GWP100 | |

| Natural refrigerant | R717 | ammonia | 0 | 0 |

| R744 | carbon dioxide | 0 | 1 | |

| R290 | propane | 0 | 3 | |

| R600 | butane | 0 | 4 | |

| R600a | isobutane | 0 | 3 | |

| Synthetic refrigerants | R1234ze | 0 | 7 | |

| R1234zd | 0.00034 | 4.5 | ||

| R1234yf | 0 | 4 | ||

Table 2: Overview of refrigerants for heat pumps and their climate impact. ODP stands for ozone depletion potential and GWP means global warming potential. Source: [1]

Types of heat source

For every heat pump project, the local availability of heat sources that can be utilized technically needs to be investigated. There are generally few restrictions regarding the heat source, which is why a wide range of possible heat sources for a heat pump are available (see table 3).

When searching for possible heat sources, attention should be paid to the source with the highest possible availability, at the same time ensuring the highest possible source temperature combined with a high energy density. The smaller the temperature difference between the heat source and heat sink, the more efficiently the heat pump can work. In addition, a high degree of availability and an almost constant source temperature have a positive impact on the resource planning and runtime of the heat pump.

| Heat source | Typical heat source temperatures | Temperature fluctuations | Typical availability |

| Ambient air | 0 to 40 °C | high | April to September |

| Surface water (e.g. rivers) | 2 to 20 °C | medium | April to October |

| Ground water | 3 to 15 °C | low | all year round |

| Sewage water | 7 to 20 °C | medium | all year round |

| Geothermal energy | 0 to 19 °C | medium | all year round |

| Waste heat | 14 to 50 °C | individual | individual |

| Flue/exhaust gases | 30 to 50 °C | low | individual |

| PV-Thermal collector field | 0 to 35 °C | high | all year round |

Table 3: Overview of heat sources and their characteristics. Source: [1]

Literature:

[1] Jens Kühne (AGFW), Praxisleitfaden Großwärmepumpen, July 2023, https://www.agfw-shop.de/leitfaeden-umsetzungshilfen/leitfaeden-erzeugung/agfw-praxisleitfaden-grosswaermepumpen.html