New fact sheets and wiki page about SHIP solutions

October 28, 2019

Two leading SHIP research institutes – the University of Kassel, Germany, and AEE INTEC, Austria – have just published their final conclusions on a binational research project called SolarAutomotive, on which they had worked together for the last three years supported by the German Foundation for Climate Protection and Resource Efficiency, STREKS. Their aim was to assess the potential for SHIP in the automotive industry, as well as identify and present successful SHIP solutions that use one of several integration concepts and supply energy to a variety of industrial processes. Among the flagship systems analysed as part of the project was a solar field of nearly 300 m² of vacuum tube collectors, which meets about 20 % of yearly oil demand at metal finishing company Heinz Daurer & Söhne (see photo).

Photo: University Kassel

As a first step, the researchers calculated the amount of heat needed at various temperature levels by German vehicle manufacturers and their suppliers in, for example, the glass, textile, leather, tire, battery and metal industries. After identifying fuel requirements in the relevant subsectors, they subtracted heat exchanger and transfer losses and, with a focus on key production processes in each subsector, assessed the amount of heat required, which came to 17,262 GWh per year under 100 °C and 6,970 GWh between 100 °C and 200 °C (see the table below). Typical processes that need up to 150 °C are washing, drying, dyeing and galvanising, while powder coating, nitriding and hardening require up to 250 °C.

Based on this demand, they calculated the potential for solar energy, subtracting 60 % from the total for efficiency reasons and because of limited space on factory roofs. Of the remaining demand, the sun can meet about 30 % throughout the year.

|

Heat < 100 °C |

From 100 °C to 200 °C |

||

|

Heat demand from vehicle manufacturing |

10,958 |

4,210 |

GWh p.a. |

|

Heat demand from supply chain businesses |

6,304 |

2,760 |

GWh p.a. |

|

Total |

17,262 |

6,970 |

GWh p.a. |

|

Cut by 60 % because of efficiency measures and limited roof space |

6,905 |

2,788 |

GWh p.a. |

|

Year-round 30 % solar share because of seasonal changes in irradiation |

2,071 |

836 |

GWh p.a. |

|

Collector area to meet heat demand (400 kWh/m²) |

5.2 |

2.1 |

million m² |

Estimated potential for SHIP at automotive manufacturers and their supply chain businesses

Source: SolarAutomotive

One of the key outcomes of the detailed sector analysis is the Solar Automotive WikiWeb, an online database created by AEE INTEC. Users can choose one of several industrial subsectors, for example, automotive, leather, metals or textile, to view a table that lists all relevant production processes. A detailed description of each process will be shown after clicking on a hyperlink in the table. The Wiki is available for free at http://wiki.zero-emissions.at/index.php?title=Solar_Automotive_Wiki

Fact sheets showing ten integration concepts

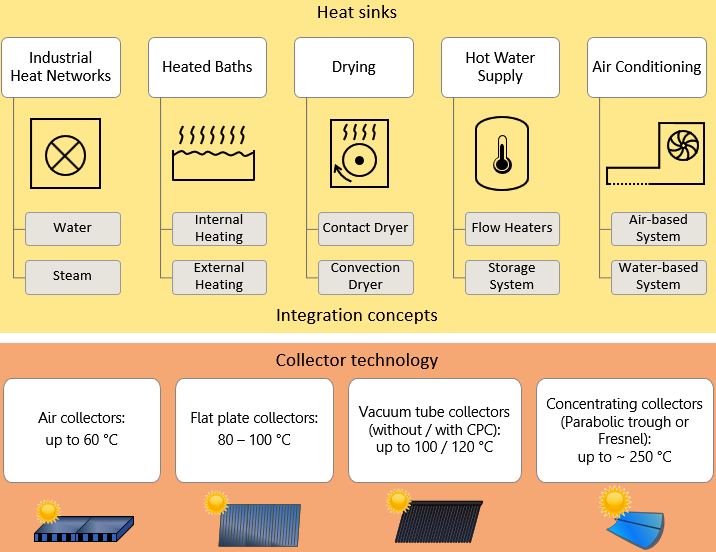

“There is a lack of easy-to-read brochures that include successful SHIP installations and that planners or engineers can show new customers to encourage them to take a closer look at solar heat technology,” explained Felix Pag, head of the Process Heat working group at the University of Kassel. The Fact Sheets brochure fills that gap (see the attached PDF). It focuses on five typical heat sinks in low temperature industrial heat demand including two different integration concepts each, which are shown in the chart below. The brochure also describes ten SHIP systems that use these integration points, with each description including detailed information about the installation, for example, the name of the customer, type of collector and solar fraction. All of them also include photos of the system.

More information:

http://www.xn--solare-prozesswrme-ztb.info/ (in German)

Organisations mentioned in this article:

http://www.streks.org/willkommen.html (under construction)