China: Solar Process Heat at “Green” Tannery

June 27, 2012

Tannery Heshan Bestway Leather, a German joint venture in the People’s Republic of China, inaugurated its new Chinese factory in Heshan on 9 June in the presence of around 300 visitors from all over the world. The factory houses a solar thermal process heat installation with 630 m² of collector area. Heshan Bestway Leather is one of the leading manufacturers in leather products on a highly environmentally friendly basis.

Tannery Heshan Bestway Leather, a German joint venture in the People’s Republic of China, inaugurated its new Chinese factory in Heshan on 9 June in the presence of around 300 visitors from all over the world. The factory houses a solar thermal process heat installation with 630 m² of collector area. Heshan Bestway Leather is one of the leading manufacturers in leather products on a highly environmentally friendly basis.

Photos: Aschoff Solar

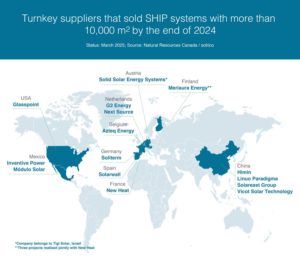

The company is a joint venture between German Bader Automotive Leather and ISA TanTec. The latter is run by Thomas Schneider, who places great emphasis on reducing energy consumption and incorporating environmental ideas in all areas of his factory. The company responsible for the solar turnkey installation is Aschoff Solar, a German solar system provider specialised in process heat installations across the highly water and energy consuming industries in Asia, with projects in Thailand, Vietnam and China.

The tannery uses solar heat in three different application areas throughout the large factory site. The biggest installation is the process heat system which preheats water for the retanning drums and vacuum dryers at 70°C (see photo). A fuel oil boiler serves as the back-up energy source. The system is non-pressurised, consisting of evacuated double-glass tubes, German control systems and active hydraulic devices.

The second solar thermal system has a collector area of 186 m² and supplies hot water to the dormitories of around 1,000 workers. This installation had already been set up in Guangzhou, China, in 2007. When Mr Schneider decided to move his production to the new factory in Heshan, the Aschoff team also moved the collector field, upgraded it by adding controller units from Germany and set up the system on the newly constructed dormitory buildings. Like the old installation, the newly mounted one consists of a non-pressurised, open-loop collector system.

The third system includes seven solar water heater units for 15 rooms in a second dormitory building in Heshan, built earlier this year. The efficient, traditional solar water heaters have been improved by additional safety functions and pumps, in order to provide hot water at highly comfortable levels.

A couple of years ago, Schneider said he would adhere to the standard “Low Impact to Environment Leather” (LITE Leather). This certificate is based on the product’s water and CO2 footprint, and involves documenting the water consumption and carbon dioxide emissions for each square meter of leather produced. Compared to the average water and energy consumption in the national leather industry, which is a value calculated by the British Leather Technology Centre (BLC), his tanning process consumes around 50 % less energy and 40 % less water.

More information:

ISA Tan Tec: http://www.liteleather.com

This news was written by Yaping Zhang, solrico partner in China (http://www.solrico.com).