PVT4EU develops and tests next-generation PVT collectors

January 23, 2026

The combination of PV module and thermal absorber – known as PVT – is available in many different designs. „There is no universally optimal PVT collector; the best solution is always application-specific,” said Iván Acosta, Project Coordinator of PVT4EU and Head of Engineering at MG Sustainable Engineering, Sweden. This is precisely why the EU-funded PVT4EU project focuses on diversifying the PVT technology portfolio by developing and validating two fundamentally different collector concepts. PVT-SP is a retrofit solution based on a polymer absorber that can be mounted on existing PV systems and used as a heat source for heat pumps in residential buildings. PVT-MG is a double compound parabolic concentrator (CPC) collector capable of delivering operating temperatures of up to 140 °C. Both prototypes have been successfully tested, and clear improvement potentials have been identified.

Photo: Technical University of Denmark (DTU)

“Our intensive scientific investigation of the two prototypes did not only lead to significant improvements in performance, cost and reducing installation complexity,” explained Acosta. ”It also resulted in several detailed technical reports documenting these findings.”

PV cells are a limiting factor in PVT systems

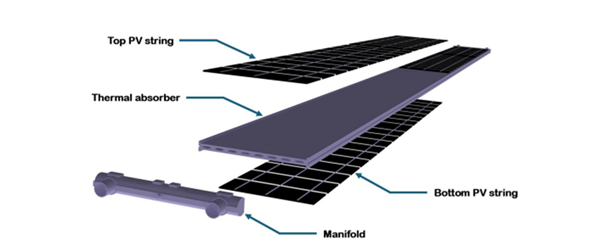

One key takeaway is that conventional, off-the-shelf PV cells are not designed for the combined thermal and mechanical stresses of PVT operation. This becomes particularly critical in concentrating PVT systems, where radiation fluxes and operating temperatures are significantly higher.

In the report on “PV Cell Technologies Assessment for PVT4EU concentrating technologies” the authors deliver a systematic assessment of PV cell technologies suitable for low-concentration PVT, analysing key indicators such as efficiency, temperature coefficient, thermal stability, cost, and scalability. The report provides a robust technical foundation for selecting PV technologies that are compatible with long-term PVT operation.You can download the report here.

Exploded view of the first-generation PVT-MG receiver. Mirrors concentrate sunlight onto the lower absorber surface. Graphic: DTU

Diversifying PVT technology

The first monitoring campaign provided valuable insights into thermal behaviour, hydraulic design, and system integration aspects of the two prototypes. It also revealed clear weaknesses related to thermal insulation, material interfaces, manufacturability, and sustainability.

These findings are now being incorporated into the design and modelling of the second-generation prototypes which are currently built at the University of Gävle in Sweden. For PVT-MG the redesign should reduce the collector weight by 25 % allowing installation by a maximum of two installers and reduce the production cost by minimum 15 % through the integration of alternative materials for the thermal absorber and concentrating structure as well as novel PV cells technology and configuration, targeting not only increased performance and cost-effectiveness but also recyclability and reparability.

The V2 collectors will be transferred to the National Laboratory of Energy and Geology (LNEG) in Portugal for the next testing campaign in the coming months. The tests will validate performance improvements under different climatic conditions and provide final performance coefficients for system-level simulations.

“Our work clearly shows that PVT development cannot rely solely on conventional PV components“, summarized Acosta. „By combining dedicated PV cell assessments, standardised testing, and eco-design principles, we aim to demonstrate how next-generation PVT collectors can become technically robust, economically competitive, and environmentally friendly.”

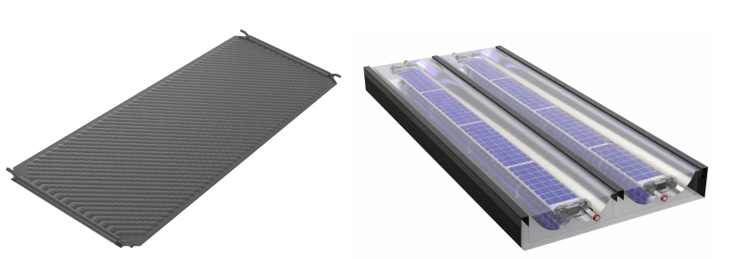

The first generation (V1) prototypes of PVT-SP (left) and PVT-MG (right) were tested according to IS0 9806 standard at DTU in Denmark in 2025. For PVT-MG-V1, the measured optical efficiency reached 55.8%, with a heat loss coefficient of 5.52 W/m²K. PVT-SP-V1 achieved an optical efficiency of 45.5%, with a heat loss coefficient of 19.24 W/m²K. Photos: PVT4EU (Talha Jahangir)

PVT collector with lowest carbon footprint

Another major outcome of PVT4EU is the strategic value of retrofit PVT solutions like PVT-SP when combined with ground-source heat pump systems. In medium- and high-latitude European regions, this approach:

- avoids the noise issues of air-source heat pumps,

- improves overall system COP,

- reduces required borehole lengths, and

- mitigates long-term ground cooling.

The PVT-SP concept uses a polymer heat absorber compatible with more than 70 % of commercially available crystalline silicon PV modules up to 450 W. Life-cycle assessment results confirm that PVT-SP exhibits the lowest global warming potential among the evaluated PVT options, mainly due to its low material demand and retrofit-based deployment.

These results are summarised in the PVT4EU Ecodesign Recommendations report, which provides concrete guidance to improve sustainability and energy efficiency and highlights the significant impact of heat transfer fluid choice on overall environmental performance. You can download the report here.

The project was funded by the Clean Energy Transition Partnership (Joint Call 2022). It started in September 2023 and is expected to be finalized in August 2026.

Websites of organisations mentioned in this news article:

PVT4EU: https://pvt4eu.eu/

Technical University of Denmark (DTU): https://www.dtu.dk/english/

National Laboratory of Energy and Geology (LNEG): https://www.lneg.pt/en/homepage/

MG Sustainable Engineering (MGS): http://www.mgsust.com

Clean Energy Transition Partnership: http://www.cetpartnership.eu