Swiss-made and cost-competitive: Sunaxer’s new approach to solar receiver coatings

January 28, 2026

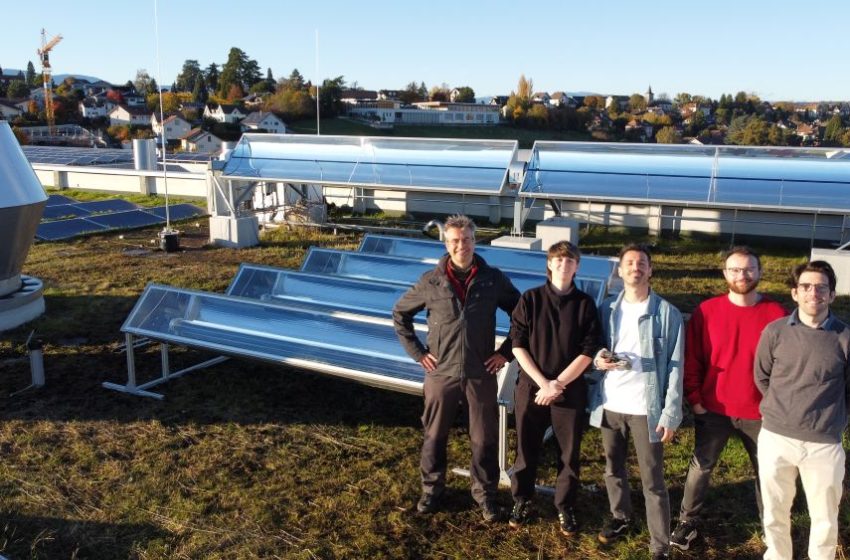

Switzerland isn’t exactly known for cost-effective production conditions. That makes it all the more remarkable that a receiver manufacturer based in Renens, near Lausanne in western Switzerland, claims to produce as cost-effectively as its competitors from Asia. We’re talking about Sunaxer, a startup founded by Anna Krammer and Maxime Lagier. Sunaxer offers an absorber tube with a triple-layered coating that remains stable in air at temperatures above 300 °C. The company has already secured its first commercial contracts and is now preparing to scale up production. The photo shows the Sunaxer team at a collector test field on the roof of the Swiss Federal Institute of Technology Lausanne (EPFL), Switzerland, which includes Sunaxer receivers. Photo: Sunaxer

Sunaxer’s core expertise lies in its proprietary coating technology. “We use a sol–gel dip-coating process to form a CuCoMn oxide nanolayer. This is significantly cheaper than sputtered coatings, as it can be carried out under ambient conditions and avoids costly vacuum processes,” explains Krammer. CuCoMn stands for copper, cobalt and manganese and these transition metals in a spinel oxide structure show good high-temperature stability. The coating process, which is protected by patents in nine countries, is based on two key innovations:

- the sol-gel coating method that requires only a minimal amount of non-hazardous chemicals (1.5 g of solution per meter of coated tube)

- an energy-efficient induction heating.

The absorber is a triple-layered coating, fabricated through three successive dipping and heating cycles. The metal oxides are formed by annealing the amorphous gel-like coating which finally results in a dense CuCoMn mixed-metal oxide coating with an absorptivity of around 96% and an emissivity of approximately 14–15%.

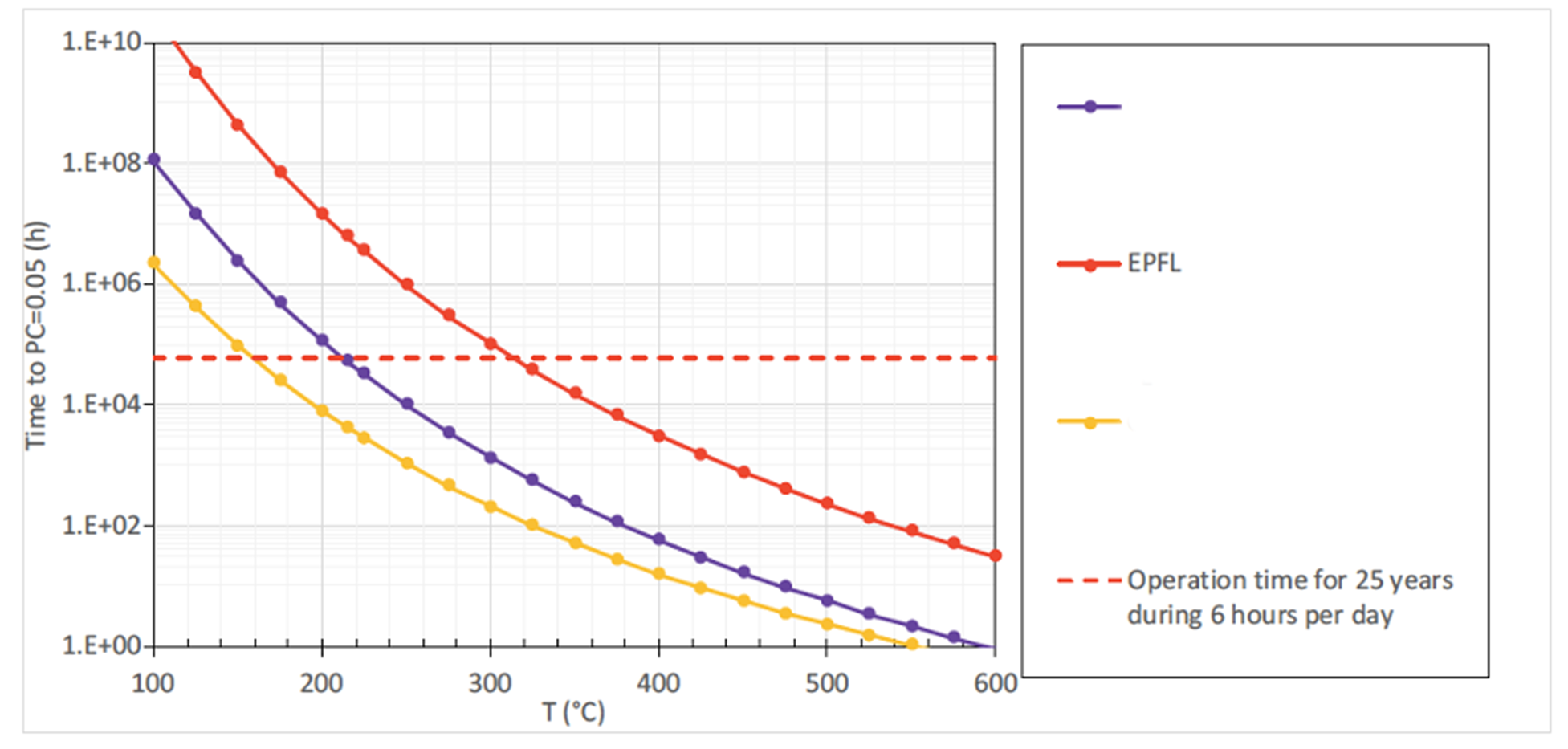

Performance criterion for degradation of solar absorber coatings

One of the key advantages of Sunaxer’s coating is its resistance to oxidation in air at elevated temperatures. In addition, the coating is sufficiently robust to be cleaned – such as to remove fingerprints incurred during manufacturing or packaging- without compromising its optical performance.

To quantify long-term stability, the degradation of solar absorber coatings in air is evaluated using a performance criterion (PC). A PC value of 0.05 corresponds to a 5 % loss in efficiency. In the chart below, the y-axis indicates the time required to reach this critical PC of 0.05, while the red dashed horizontal line marks a service lifetime of 25 years, assuming six hours of operation per day.

Sunaxer’s coating, shown by the red curve, reaches a PC of 0.05 only after 25 years of operation at 310 °C in air. This performance significantly exceeds that of comparable commercially available absorber coatings.

Measurements of performance criterion PC=0.05 at various temperatures for different receiver coatings. The red line marked EPFL is the coating from Sunaxer. Source: French National Institute for Solar Energy (INES)

Sunaxer’s expansion in receiver production

“In our Renens production facility, we are able to manufacture receivers up to 3 m in length and 42 mm in diameter,” stated Krammer. “Last year, we successfully completed our first commercial orders, delivering approximately 1,260 m of receivers to Helioclim in France and Absolicon in Sweden. Follow-up orders will bring our total deliveries to 2,000 m by April 2026.” The current production capacity in Renens stands at 9,000 m receiver length per year.

“We can offer as roughly the same price as our Chinese competitors, but with significantly shorter lead times of around two months and fewer reliability issues,” said Krammer. She added that the metal tubes are heated using an induction coil, which currently imposes certain constrains on tube geometry. However, as demand grows, Sunaxer can invest in a larger induction system, enabling the production of tubes with greater diameters and lengths.

Coated metal tube from Sunaxer. The Swiss startup company supplies coated tubes to manufacturers of parabolic trough and Linear Fresnel collectors, where they are assembled to complete receiver units. Photo: Sunaxer

Sunaxer is now at a decisive stage in its development: the technology has been successfully validated, but further growth depends on scaling up production and achieving strong market traction. Founded in 2021, the company has secured CHF 1.8 million in non-dilutive funding and convertible loans to support its expansion.

Websites of organizations mentioned in this news article:

Sunaxer: https://www.sunaxer.com/

Swiss Federal Institute of Technology Lausanne (EPFL): https://www.epfl.ch/en/

French National Institute for Solar Energy (INES): https://www.ines-solaire.org/en/